Anyone who spends their days around vertical mills—whether as a machinist or a CNC specialist—has almost certainly crossed paths with a lathe machine. Despite the leaps in technology that have brought lathes into the modern era, these machines trace their origins all the way back to ancient Egypt, around 1300 BCE, making them one of the oldest tools still in use.

By the late 16th century, particularly around 1569 in France, lathes were primarily used for shaping wood. It wasn’t until the Industrial Revolution swept through 18th-century England that the metal lathe truly came into its own, transformed by new techniques and the demands of industrial manufacturing.

In the following sections, I’ll walk you through what makes these machines unique, the variety of lathes you might encounter, practical tips for learning to operate one, and other useful insights. Let’s dive in.

What is a Lathe?

A lathe serves as a fundamental machine tool in both woodworking and metalworking, enabling the precise shaping of materials. The process involves rotating a piece of wood or metal around a central axis, while a fixed cutting tool gradually removes excess material until the intended form is achieved.

Lathes are remarkably versatile, handling a wide array of fabrication tasks such as cutting, grinding, knurling, drilling, deforming, facing, and turning.

Each of these operations relies on the interaction between the stationary tool and the spinning workpiece, which makes it possible to produce objects with symmetry around the axis of rotation.

In practice, lathes find applications not only in traditional woodturning and metalworking but also in areas like metal spinning, thermal spraying, parts reclamation, and glass shaping. Even pottery benefits from this technology the classic example being the potter’s wheel.

Well-equipped metalworking lathes are particularly valuable, as they can manufacture a broad range of forms, including solids of revolution, flat surfaces, and even complex features like screw threads or helixes.

For those interested in ornamental work, specialized lathes are capable of creating intricate three-dimensional designs with remarkable precision. Typically, the workpiece is secured by one or two centers—at least one of which can be moved horizontally to accommodate various lengths.

Alternative holding techniques include using a chuck or collet to grip the piece along the axis of rotation, or attaching it to a faceplate with clamps or a jaw clutch.

The range of products that can be made on a lathe is quite extensive. Common examples include screws, candlesticks, gun barrels, cue sticks, table legs, bowls, baseball bats, woodwind instruments, and crankshafts, demonstrating just how essential this tool is across many different fields.

How Does a Lathe Work?

A lathe is a fundamental machine tool widely used for shaping both metal and wood. Its operation centers on rotating the workpiece while a fixed cutting tool gradually removes material.

This approach allows the operator to refine the workpiece’s shape, carefully stripping away excess material to achieve the desired form.

While lathes come in various designs, the underlying principle remains consistent: the workpiece turns against a stationary cutter. This contrasts with milling machines, where the cutting tool spins and the workpiece itself stays still a clear distinction that shapes how each tool is applied in practice.

The design of a lathe enables precise and efficient material removal. Once the workpiece is secured typically to the headstock it is set in motion and brought into contact with the cutting tool. This combination of rotational movement and steady cutting enables both speed and accuracy in shaping.

Lathes are complex pieces of equipment, made up of several key components. The headstock is responsible for holding and spinning the workpiece, providing the central axis of rotation.

On the opposite end, the tailstock can be used to support longer or heavier workpieces, offering extra stability when needed. Each element of the lathe plays a role in ensuring the operator can work safely and achieve a high level of precision.

Parts of a lathe

The Main Parts of the Lathe Machine are:

- Headstock: Positioned on the left side of the lathe, the headstock houses essential components such as gears, spindles, chucks, speed control levers, and feed controls. This assembly manages both the rotation and the speed adjustments of the workpiece, serving as the operational hub at one end of the lathe.

- Tailstock: Situated on the opposite side, typically the right, the tailstock provides crucial support to the workpiece during machining. By securing the end of the material, it helps maintain alignment and stability throughout the operation.

- Bed: Acting as the backbone of the lathe, the bed supports and connects all major assemblies. Everything—from the headstock and tailstock to the carriage rails and auxiliary components—is securely fastened to the bed, ensuring structural integrity and precise alignment.

- Carriage: Found between the headstock and tailstock, the carriage includes the apron, saddle, composite support, cross slide, and tool holder. Its primary function is to guide and support the cutting tool as it moves along the workpiece.

- Lead Screw: When it comes to threading, the lead screw plays an indispensable role. It provides automatic movement to the carriage, making precision thread cutting possible.

- Feed Rod: The feed rod is responsible for driving the carriage horizontally along the bed, allowing for controlled, consistent motion either to the left or right, as required by the machining process.

- Chip Pan: Located beneath the lathe, the chip pan collects metal shavings and debris produced during machining. This feature keeps the workspace cleaner and helps prevent buildup around critical components.

- Hand Wheel: Several parts of the lathe, including the cross slide, carriage, and tailstock, are adjusted manually using hand wheels. These provide the operator with fine control over movement and positioning.

- Chuck: The chuck is designed to securely hold irregularly shaped workpieces, those that do not fit typical round, square, or triangular profiles, making it a versatile fixture for a variety of machining tasks.

- Cooling Device: A cooling system is integral for both performance and tool longevity. Using a water pump, coolant is directed onto the cutting area to manage temperature, wash away chips, and promote smoother surface finishes on the workpiece. This also contributes to improved tool life and overall machining quality.

- Legs: Lathes rest on sturdy cast legs, which support the entire machine’s weight. These legs are typically anchored to the floor to minimize vibration and ensure stable, precise operation.

- Slide Box: Serving as the control center for feed movements, the slide box translates the rotary motion from the lead screw or feed rod into linear motion for the tool post. This mechanism is essential for accurate tool advancement.

- Spindle: The spindle is a hollow shaft running through the headstock, allowing bar stock to be fed through. This design enables the machining of longer shafts, sometimes up to twice the distance between centers, by working on one end at a time.

- Cross Slide: Mounted on the carriage’s traverse slide, the cross slide lets the operator feed the cutting tool into the workpiece with precision, usually controlled by a dedicated hand wheel.

- Apron: Fastened to the front of the carriage, the apron contains the controls and mechanisms responsible for moving both the carriage and cross slide, giving the operator direct access to crucial adjustments during machining.

Types of lathes

The following are different types of lathe machines:

- Center lathe or engine lathe

- Speed lathe

- Capstan and turret lathe

- Toolroom lathe

- Bench lathe

- Automatic lathe

- Special lathe

- CNC lathe machine

The most common machine tool is a lathe, which can be divided into different types according to different processing conditions for the turning process.

1. Center lathe or Engine lathe

This particular type of lathe has become commonplace in modern workshops, valued for its ability to handle a range of tasks such as turning, facing, grooving, knurling, and threading.

One notable feature of the engine lathe is its feed mechanism, which enables the cutting tool to move both longitudinally and laterally, offering versatility for different machining requirements.

When it comes to the center lathe, its classification largely depends on the drive source. Typically, these lathes are categorized as belt-driven, motor-driven, or equipped with a reduction gear system.

Each configuration comes with its own set of advantages, but the overarching appeal remains the same: center lathes are relied upon today precisely because they manage essential operations like turning, grooving, knurling, facing, and threading with consistency and precision.

2. Speed Lathe/Wood Lathe

Lathes of this kind may be designed as table models or constructed with integral support legs that are cast and joined to the bed. While they generally accommodate most of the attachments found on other lathe varieties, they do not include a provision for power operation.

A high-speed lathe, often referred to as a wood lathe, is capable of manual operation at elevated speeds, typically within the range of 1200 to 3600 RPM. This type of lathe is particularly suited for tasks such as turning, centering, polishing, and various wood-processing applications.

Unlike other lathes, this model is not equipped with gears, slides, or a lead screw. Instead, the operator advances and manipulates the tool entirely by hand.

The tool is usually positioned on a dedicated stand or supported with a T-shaped rest. These lathes find common use in operations like turning, polishing, centering, and even metal spinning.

3. Capstan and turret lathe

Capstan and turret lathes represent a significant advancement over traditional engine lathes, particularly when it comes to handling high-volume production or larger workpieces. What sets these machines apart is the hexagonal turret head.

This feature allows the operator to rotate the head and switch between different machining operations, such as turning, facing, boring, and reaming, without needing to change tools by hand each time.

This design not only streamlines the process but also boosts efficiency, making these lathes especially valuable in settings where speed and repeatability are crucial.

4. Toolroom lathe

Essentially, this is a standard power lathe that has been enhanced with additional attachments, allowing for greater precision in adjusting speeds and feeds. Common accessories found on such machine tool lathes include tapered turning attachments, driver supports, collets, and chucks.

Compared to the typical motorized lathe, this model features a bed that is somewhat smaller in width but longer in length, with standard sizes usually ranging from 135 to 180 centimeters.

5. Bench lathe

This type of lathe is compact in size and is usually installed on a dedicated workbench or cabinet. Despite its small footprint, it offers a high degree of accuracy, making it ideal for tasks that require precision.

Interestingly, it can be fitted with the same range of attachments as its larger counterparts, which means it is fully capable of handling most operations you would expect from a full-sized lathe.

6. Automatic lathe

These lathes significantly enhance both the quality and efficiency of production. Their design allows for the entire sequence of manufacturing and order processing tasks to be performed automatically, with no need for operator intervention during actual operation.

There is also a variation known as the semi-automatic lathe, where the operator’s role is limited to loading and unloading the workpiece; the machine itself handles all other processes automatically.

Automatic lathes come in both single-spindle and multi-spindle configurations. As high-speed, high-performance machines, they are especially valued in environments focused on large-scale, repetitive production.

7. Special lathe

There are certain machining tasks that standard lathes simply cannot handle, which is where special lathes come into play. These machines such as vertical lathes, wheeled lathes, T-type lathes, multi-axis lathes, production lathes, and duplex or tracer lathes are specifically designed for specialized operations.

What sets these lathes apart is their capacity for heavy-duty, repetitive production of identical parts, making them essential in settings where consistency and high output are required.

8. CNC lathe

A CNC lathe operates by following instructions set out in a computer program, allowing for precise and efficient control over the machine’s functions. Once the steps of the program have been entered, the machine can handle large-scale production with impressive speed and accuracy.

Notably, after the operation codes are established, there is no need to input them again for subsequent runs, which streamlines the process even further.

Among modern lathes, CNC models represent the highest standard in terms of technological advancement. They are capable of producing components with remarkably tight tolerances, making them indispensable where exact measurements and consistency are critical.

Lathe Operations

When working with a lathe, some operations come up more frequently than others. You’ll often find yourself turning, facing, grooving, parting, threading, drilling, boring, knurling, or tapping, depending on the task at hand.

Before getting started, it’s important to have a handle on a few key parameters: feed rates, cutting speed, depth of cut, and the specific way each tool should be used. Each operation has its own set of considerations, so taking a moment to think these through can save a lot of trouble down the line.

If these factors aren’t handled carefully, there’s a real risk of mistakes or even accidents, regardless of which operation you’re performing. For every new cut, the speed, depth, and feed should be adjusted—not just out of habit, but because each detail affects the precision of your work.

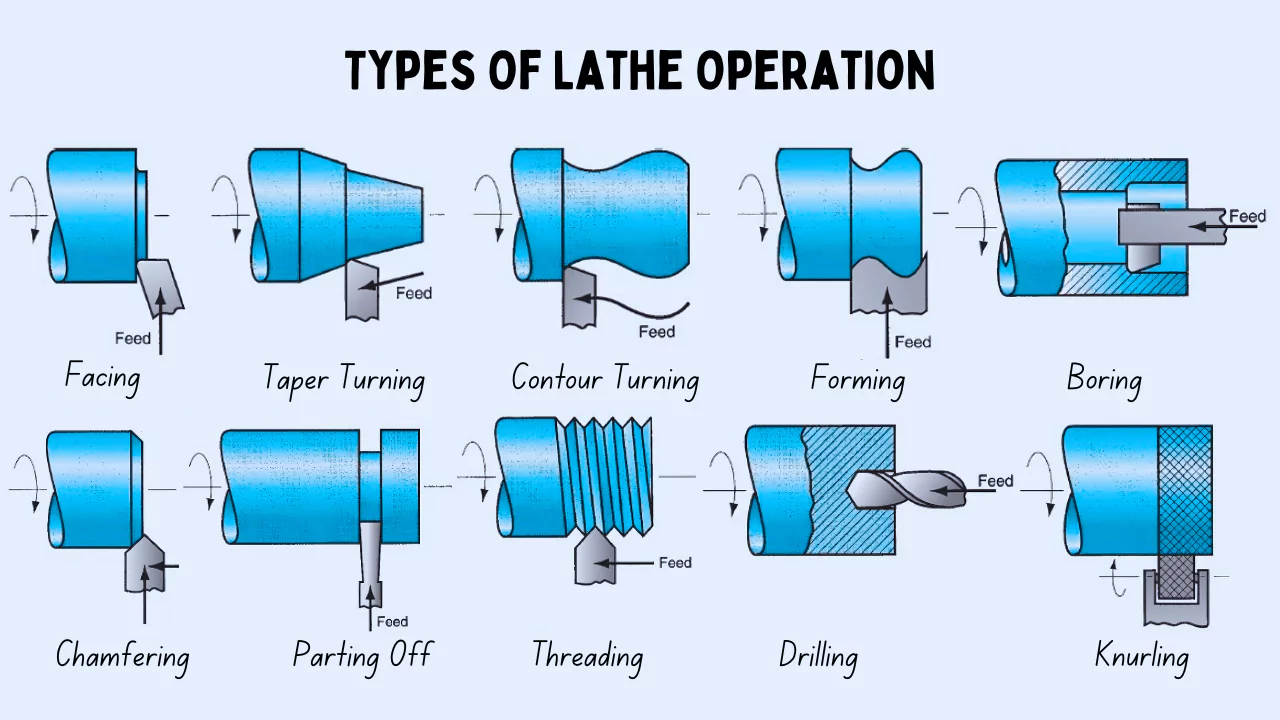

Types of Lathe Operation

The working of the lathe machine changes with every operation and cut desired. There is a lot of operation used for using the lathe machine. Some of the common lathe operations are:

1. Turning

Turning stands out as the most widely used operation on a lathe. In essence, this process involves a cutting tool removing material from the outer surface of a rotating workpiece, gradually bringing its diameter down to a specific size. The primary aim is straightforward: to reduce the workpiece to the required dimension. Generally, turning falls into two categories—rough turning and finish turning.

With rough turning, the focus is on speed and efficiency. Here, the operator removes as much material as possible, as quickly as possible, aiming to get close to the final size without worrying too much about accuracy or surface smoothness. On the other hand, finish turning is all about precision. This stage produces the final dimensions and gives the workpiece a smooth surface.

A single part may need sections with different outer diameters. The shift between these surfaces isn’t always abrupt; depending on the design, it might feature a step, a taper, a chamfer, or a more complex contour. Achieving these transitions often calls for several passes of the cutting tool, each taking off a thin layer.

- Rough Turning: This operation quickly brings the workpiece to within a rough size, removing material rapidly and sacrificing accuracy and surface finish for speed. The finish turning stage follows, where the emphasis shifts to hitting the exact dimensions and improving surface quality.

- Step Turning: Here, the tool shapes the workpiece to create two sections with a sudden change in diameter, producing a clear, step-like transition.

- Taper Turning: Taper turning introduces a gradual, sloped change between two surfaces of different diameters. This effect is achieved by moving the cutting tool at an angle to the axis of rotation, resulting in a ramp-like profile.

- Contour Turning: This method involves guiding the tool along a predefined path to form smooth, curved surfaces. Usually, several passes are necessary to develop the desired contour, although using a molding tool can create the shape in just one pass.

- Chamfer Turning: Chamfer turning (sometimes called bevel turning) replaces a sharp corner with an angled edge, providing a sloped transition between two surfaces with different diameters.

- Form Turning: For form turning, a specially shaped tool is pressed into the workpiece to generate a specific profile. This is typically done with a radial feed. In practice, lathe operations like facing, forming, and contour turning may all be required to achieve the final shape of the part.

2. Facing

In machining processes, it is common practice to make workpieces slightly longer than the final dimensions required for the part. Facing is a technique used to finish the end of a workpiece, ensuring it is perpendicular to the axis of rotation.

During facing, the cutting tool moves outward along the radius of the workpiece, carefully removing a thin layer of material. This not only brings the part to its intended length but also produces a smooth, even surface at the end.

3. Parting

Parting is a machining process in which a component is separated from the main stock at the conclusion of the machining cycle. To accomplish this, a specially shaped tool moves into the workpiece at a right angle to the rotating axis, making a steady, controlled cut as the workpiece continues to spin.

Once the tool’s edge reaches the center point of the workpiece, the finished part detaches and falls away. In practice, a part catcher is usually positioned to safely receive the separated piece and prevent it from being damaged as it drops.

4. Grooving

Grooving is a machining technique used to produce a narrow cut, known as a “groove,” on a workpiece. The width of this cut is determined by the size of the cutting tool employed. When a groove wider than the tool’s width is needed, multiple passes of the tool are necessary to achieve the desired dimension.

Grooving operations are generally classified into two categories: external grooving and face grooving. In external grooving, the cutting tool moves radially and laterally into the workpiece, removing material along the direction of the cut. Conversely, face grooving involves the tool penetrating the face of the workpiece to create the groove.

5. Threading

Threading is a machining operation where a tool travels along the workpiece’s exterior to cut threads on its surface. These threads form a consistent spiral groove characterized by a defined length and pitch. When deeper threads are needed, the process involves making several passes with the cutting tool.

6. Knurling

The knurling process involves producing serrated patterns on the surface of a component. This technique enhances both the grip and the aesthetic appeal of the machined part. It is performed using a specialized tool composed of one or more cylindrical wheels, known as knurls, which rotate within the tool holders.

These knurls have teeth that are pressed and rolled against the workpiece surface, creating the serrated design. Among the various patterns, the diamond-shaped knurl is the most frequently used.

7. Boring

Boring involves the axial insertion of a tool into a workpiece, where it removes material from the inner surface. This process is used either to enlarge an existing hole or to shape the interior in various ways.

8. Drilling

When drilling, material is extracted from the inside of a workpiece, producing a hole whose diameter matches that of the drill bit employed. Typically, drills are mounted either on a tailstock or held in a lathe tool holder.

9. Reaming

Reaming is a calibration technique used to slightly enlarge an existing hole in a workpiece. During the process, the reamer is guided axially into the hole, gradually expanding it to match the tool’s precise diameter.

This method removes only a small amount of material and is typically performed after drilling. Its primary purpose is to refine the hole’s diameter for greater accuracy and to improve the smoothness of the internal surface.

10. Tapping

Tapping involves using a thread-cutting tool to axially penetrate a workpiece and create threads inside a pre-existing hole. The hole size is matched to the appropriate bit size that fits the chosen thread-cutting tool. Additionally, tapping refers to the process of forming threads on nuts as well.

Lathe Tools

For general tasks, a single-point cutting tool is typically employed; however, multipoint tools are utilized for specialized operations. To gain a clearer understanding of lathe machine operations, please refer to the video provided below.

In lathe machining, various operations demand specific types of cutting tools. The selection of these tools depends on the particular process being performed with the lathe. The main types are as follows:

Types of Lathe Cutting Tools

Different Types of Lathe Cutting Tools:

- Turning Tool.

- Boring Bar

- Chamfering Tool

- Knurling Tool

- Parting Tool

- Thread Cutting Tool

- Facing Tool

- Grooving Tool

There is a wide range of lathe tools that can be classified according to materials, structures, and purposes or uses.

- Turning Tool: Turning tools are primarily used to remove material from a workpiece. A rough turning tool is intended to take off the bulk of the material quickly, whereas a finishing turning tool is used to improve surface quality by removing only a small amount of material, ensuring greater accuracy in the final piece.

- Boring Bar: When the goal is to enlarge an existing hole, a boring bar comes into play. It can easily enter a pre-drilled hole and increase its diameter efficiently, allowing the hole to be resized accurately to accommodate other components.

- Chamfering Tool: A chamfer refers to the angled transition between two faces of an object, essentially a type of bevel. Chamfering tools create these bevels or grooves, which serve to smooth out sharp or potentially dangerous edges on a workpiece, improving safety and fit.

- Knurling Tool: Knurling tools are designed to imprint a pattern onto cylindrical surfaces, typically to provide grip on handles or fasteners such as nuts. These tools press or cut a specific, repeated pattern onto the surface to enhance functionality and aesthetics.

- Parting Tool: A parting tool features a narrow blade used to cut off sections from the main stock during turning or planing operations. This tool comes in various forms and is essential for separating a finished piece or removing unwanted material.

- Thread Cutting Tool: Thread cutting tools are used to create threads on a lathe part. For external threads, the workpiece is either clamped in a chuck or held between centers, while for internal threads, the piece is held in a chuck. The tool moves linearly along the part, removing material to form the thread with each pass.

- Facing Tool: Used to produce flat surfaces perpendicular to the rotational axis of a workpiece, the facing tool is mounted on a tool holder resting on the lathe’s carriage. It feeds across the face of the piece to create a smooth, flat finish.

- Grooving Tool: Typically equipped with a carbide insert, grooving tools are mounted in specialized holders and often feature multiple cutting tips. These tools are ground to specific shapes and dimensions, allowing them to cut slots or perform other detailed operations.

- Forming Tool: Forming tools can be flat or circular and are shaped according to the groove, undercut, or thread profile they need to cut. Simple forming tools have cutting edges precisely ground to match the desired shape on the lathe.

- Shoulder Turning Tool: Turning square shoulders involves a knife-edge or facing tool. For beveled shoulders, a straight turning tool with a side cutting edge angle and zero nose radius is used, while filleted shoulders require a straight turning tool with a nose radius matching the fillet radius of the workpiece.

- Counterboring Tool: Counterboring operations may be carried out using a standard boring tool whose cutting edge is ground to create a shoulder. More commonly, counterbores have multiple cutting edges for efficient material removal and accurate shoulder formation.

- Undercutting Tool: Undercutting or grooving tools have cutting edges shaped exactly to the required groove profile. Clearance angles are provided on all sides, with the longitudinal feed applied during recess groove cutting. The front clearance angle depends on the bore diameter of the workpiece.

Application of Lathe

The lathe machine serves various purposes across different manufacturing processes, including the following:

- It is primarily used to create round or partially round components.

- The machine is capable of cutting both male and female threads.

- It facilitates the cutting off of excess material.

- Boring and drilling holes, as well as knurling knobs, are common operations performed on a lathe.

- Polishing the surface of round parts and tapering shafts are also among its applications.

- The lathe can face or dress rough stock to prepare it for further machining.

- Although milling is typically done on a milling machine, small parts can be milled on a lathe by mounting a cutter and securing the workpiece on the tool post.

- The lathe can power devices such as hydraulic pumps that lack their own motors, allowing control over the shaft’s direction and speed, provided it fits in the chuck.

- While primarily used for metal, plastic, and wood, the lathe can accommodate a variety of materials with few practical restrictions.

- It is useful for aligning two broken shaft pieces before repair.

- Finally, the lathe can bevel edges to achieve the desired shape.

Advantages of Lathe

The advantages of using a lathe machine can be summarized as follows:

- CNC lathes offer significantly greater accuracy compared to traditional machining lathes.

- These machines support a higher rate of production.

- Operating them does not require highly specialized skills.

- The process is fully automated, which simplifies and speeds up the work involved.

- Both lathe and CNC lathe machining operate at a rapid pace.

- They are highly versatile, capable of manufacturing a wide variety of products and parts.

Disadvantages of Lathe

The limitations of the lathe machine can be summarized as follows:

- Inadequate maintenance, particularly the lack of proper lubrication, can lead to damage of the machine’s components.

- The machine experiences accelerated wear if operated by individuals lacking sufficient skill or experience.

- The high speed of the cutting process often produces strong odors in the surrounding environment, which may have adverse health effects.

- Compared to other conventional machines, lathes tend to be more expensive, largely because they are capable of performing a wide range of operations.

FAQs

What is a lathe used for?

A lathe is a machining tool that is used primarily for shaping metal or wood. It works by rotating the workpiece around a stationary cutting tool. The main use is to remove unwanted parts of the material, leaving behind a nicely shaped workpiece.

What is the basic of lathe?

A lathe is a machine tool that processes metal by rotating the material to be processed and applying a blade to cut it into a cylindrical shape. For a simple example, imagine peeling an apple.

What is a lathe construction?

A lathe consists of four main parts: the bed, spindle, turret, and tailstock. Briefly, the main spindle holds the material and rotates it. The turret, where the tool is attached, moves to shape the part to be machined.

What tool is a lathe?

A lathe is a machine that rotates the piece on the axis in order to perform various operations like cutting, facing, knurling, deformation, and more.

What is the difference between a lathe and a turning machine?

Lathes are primarily used in processing cylindrical shapes such as cylinders, cones, and spheres. However, they have limited capabilities for complex geometries and secondary machining operations. On the other hand, turning machines can handle a wide range of part shapes and geometries.