What is a Punch Tool?

A punch is a handheld tool designed to create indentations or perforate hard surfaces. It’s typically made from a durable metal rod, shaped with a narrow, pointed tip on one end and a broader, flat surface—often referred to as the butt on the other.

In practice, the pointed tip is placed against the material being worked on, and the flat end is struck with a hammer or mallet. This impact drives force down the length of the rod and concentrates it at the tip, allowing it to mark or penetrate the surface.

For woodworking tasks, a ball-peen hammer is commonly used in combination with a punch to achieve precise results.

Structurally, a punch is relatively simple: a slender metal rod with a sharp end for contact and a wider end meant to absorb impact. To use it, the user aligns the sharp tip with the target spot, then strikes the opposite end using a hammer or mallet. This sudden force drives the point into the material, producing a hole or indentation.

While punches come in various forms, most share this basic functionality. They rely on an external striking tool to deliver the necessary force, making them essential for tasks that require precision marking or starting a hole for drilling.

Hollow vs Solid Punch Tools

Punch tools generally fall into two categories based on their internal structure: hollow and solid. As the names suggest, hollow punch tools feature an empty interior, while solid punch tools are completely filled inside.

Hollow punches are typically used for cutting clean holes through a material’s surface by piercing it. Solid punches, in contrast, serve a slightly different purpose they’re often used to either remove bits of material or to drive items like pins or rivets into a workpiece.

Types of Punch Tools

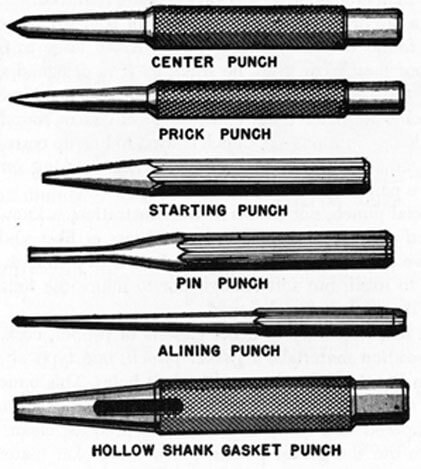

In mechanical engineering workshops, punches are indispensable tools, each designed for specific tasks. Among the most commonly used types are the center punch, prick punch, pin punch, and drift punch.

These punches serve a range of purposes. For instance, they help in marking the centers where circles are to be drawn, creating indentations in sheet metal, initiating holes before drilling, and even removing damaged fasteners like rivets, bolts, or pins.

In some cases, punches are also used to accurately transfer hole locations from a template or pattern onto a workpiece. It’s worth noting that certain types of punches especially those used for extraction are hollow to accommodate broken components.

Types of punches are as follows:

- Centre punch

- Prick punch

- Solid punch

- Transfer punch

- Drive punch

- Pin punch

- Roll pin punch

- Hollow punch

- Dot punch

- Letter stamps

- Tablet punch

1. Centre Punch

A center punch is a simple yet essential tool used to accurately mark the center point on a material surface, most commonly in preparation for drilling. This mark serves as a guide, preventing the drill bit from slipping or “wandering” off its intended path when starting a hole.

By creating a small dimple at the precise spot, the center punch ensures that the drill bit engages the surface exactly where needed.

Typically, the tip of a center punch is shaped at an angle between 60 and 90 degrees. While this is sufficient for most standard applications, in cases where larger holes are required and where the diameter of the drill bit exceeds that of the punch indentation it is often necessary to first create a pilot hole.

This smaller hole helps guide the larger drill bit more effectively and ensures cleaner, more accurate results.

There are two main types of center punches: manual and automatic. The traditional manual version requires a hammer to strike the punch and form the dimple. In contrast, an automatic center punch eliminates the need for a separate striking tool.

It is spring-loaded and designed to deliver a controlled impact simply by pressing it against the workpiece. As pressure is applied, the internal spring compresses and then releases energy, delivering a sharp, consistent impulse that forms a uniform indentation.

This consistency makes the automatic center punch especially useful for tasks that require repeatable accuracy.

Applications:

The automatic center punch mechanism has been used for a wide variety of other applications. These include

- Marking and starting a hole for drilling without the bit “walking” out of alignment

- Letter stamp sets

- Glass-breaking tools used in rescue work and a common tool for a car thief.

- Impact tool for hardness testing

- Pin presses for electronic assembly

- In many applications, such as hardness testing, the mechanism does not have an adjustment for impulse strength, and may require periodic calibration checks.

2. Prick Punch

A prick punch, often referred to as a dot punch, shares similarities with a center punch but is primarily used for layout and marking tasks.

What sets it apart is its sharper tip—typically ground to an angle of around 40 degrees, though this may vary depending on the specific type in use. This sharper angle allows it to create a narrower and deeper indentation, ideal for precision marking.

Once the initial mark is made with a prick punch, it can be followed up with a center punch to widen the indentation, making it more suitable for accurate drilling.

In terms of material, prick punches are generally manufactured from high carbon steel, which is then hardened and tempered to withstand repeated impact and maintain its sharpness over time.

3. Solid Punch

Solid punches are single-piece, rod-shaped tools typically made from metal and designed to be struck with a hammer. Their primary function is to drive components like pins or to create impressions in a workpiece.

Depending on the specific task, these punches come in a variety of diameters, lengths, and tip shapes to suit different needs.

In blacksmithing and sheet metal work, solid punches are frequently used for boring holes. The size of the punch is selected based on the specific requirements of the job at hand. These tools are generally made from high-carbon steel, which is then hardened and tempered to improve durability and performance.

When working on hot materials, it’s important to cool the punch in cold water during use to prevent overheating and damage. However, it’s worth noting that solid punches are better suited for rough work. The holes they produce often lack precision in terms of exact measurements and tend to have a less clean finish compared to other methods.

4. Transfer Punch

A transfer punch is a specialized tool typically part of an indexed set designed with a consistent outer diameter that runs the full length of the punch, aside from the tip.

Unlike tapered punches, it maintains uniformity to ensure a snug fit within an existing hole. This design allows it to accurately mark the center point of that hole onto another surface when struck.

This tool comes in handy in various precision tasks. For instance, it’s often used to replicate hole patterns from one part to another or to mark exact locations for drilling and tapping threaded holes. This ensures proper alignment when bolting components together or attaching a part securely to a surface.

5. Drive Punch

A drive punch is a practical tool commonly used for making clean, accurately-sized holes in materials like leather or fabric. To use it, you position the punch over the material, place it on a cutting surface, and strike it with a mallet.

The tool is made of high quality steel, and one useful feature is that it clears out the punched material through a side opening so there’s no need to worry about clogging during use.

Aside from crafting, drive punches are also essential in mechanical tasks, particularly when you need to remove damaged rivets, bolts, or pins that are stuck inside holes. Unlike pointed punches, the drive punch has a flat striking surface.

Its size is typically defined by the diameter of this flat face common sizes include 1/8-inch or 1/4-inch. The body of the punch usually tapers smoothly down to this flat tip.

However, in some situations, especially when a straight shaft is required, you’d opt for a different tool like a pin punch or drift punch, which are designed with a straight shank.

In practical use, you’d begin by placing the drive punch against the stuck pin or bolt. You tap it with a hammer or mallet to push the pin through until it can’t go any farther because the hole narrows or blocks the punch from proceeding further.

6. Pin Punch

Pin punches differ noticeably from other types of punches, primarily in both shape and function. They tend to be longer and have a straight, parallel design rather than a pointed tip. This structure makes them particularly effective for working with tight-fitting pins.

Unlike other punches, pin punches are specifically designed to push rivets or pins all the way through a hole until they are fully removed. This is something standard punches aren’t typically suited for. After loosening a bolt or pin, a pin punch allows you to drive it completely out of its position.

It’s important to avoid using tools like prick punches or center punches for this task—because of their pointed tips, they can actually deform the pin or bolt, making it even harder to extract.

7. Roll Pin Punch

Spring punches, commonly known as roll pin punches, are specifically designed for driving roll pins. It’s important to note that standard pin punches should never be used for this purpose.

Roll pins have a hollow, thin-walled construction, and using a standard punch can easily cause damage crushing or distorting the end of the pin, or even pushing the punch into the hollow center where it can become jammed.

When selecting the right roll pin punch, size matters. You’ll want to choose one that matches the compressed diameter of the pin no larger, no smaller. If the punch is oversized, you risk damaging the surrounding metal where the pin is seated.

On the other hand, if the punch is too small, it can slip inside the hollow core of the roll pin, potentially ruining both the tool and the pin.

What makes a roll pin punch unique is the small raised projection at the center of its tip. This design helps to support the edges of the roll pin as you drive it.

Because of this projection, these punches should only be used on roll pins. Using them on solid pins will almost certainly leave marks or damage the pin’s surface.

It’s also worth keeping an eye on the condition of the tool. If the tip of a roll pin punch becomes damaged or deformed, it’s best to replace it. Regrinding the tip and reshaping the center projection accurately is nearly impossible, and a compromised tool can do more harm than good.

Finally, technique matters. When using a roll pin punch, always keep the punch aligned straight with the roll pin don’t angle it off to one side. And when you strike it, hit the top of the punch squarely.

Striking it at an angle can bend the shank, which not only affects the performance of the punch but can also damage the pin or the surrounding assembly.

8. Hollow Punch

A hollow punch is a specialized tool crafted from hardened steel, designed with a hollow cylindrical body. Its primary function is to create precise holes in various materials such as metal, cardboard, and fabric.

These punches are typically available in sets, offering multiple sizes to suit different hole dimensions. Thanks to their hollow design, the removed material is efficiently expelled through side grooves, allowing for quick and consistent punching. This not only saves time but also results in clean, well defined holes.

Hollow punches are especially useful for working with softer materials like gaskets, leather, rubber, plastic, vinyl, and canvas.

They’re commonly employed in leather crafting, garment production, and accessory design ideal for tasks involving belts, jackets, handbags, and custom leather goods. Their precision and ease of use make them a staple in both industrial and craft applications.

9. Dot Punch

A dot punch closely resembles a center punch in both form and function, though it is generally slimmer, lighter, and equipped with a sharper tip. Its primary role is to mark the center of a hole that is intended to be drilled, but it’s also commonly used for creating small indentations on a surface.

Thanks to its finer tip, the dot punch produces more precise marks, which makes it particularly useful when accuracy matters.

Despite the slight design differences, dot punches and center punches are used in the same manner. Typically, a ball pein hammer is lightly tapped against the head of the punch.

This action transfers force through the tool to its pointed end, creating a small, clean indentation in the material beneath. It’s a simple but effective technique that helps guide drill bits or align components during fabrication.

11. Letter Punch

Letter punches—sometimes referred to as letter or number stamps—are tools designed to imprint letters or numbers onto a workpiece by physically embossing their shape into the material.

Typically, these punches are manufactured with reverse images of the characters. This design choice ensures that once the impression is made, the result appears correctly oriented and legible at a glance.

In specific applications like die or mold making, this reverse format becomes especially important. Since dies function as negative molds, using a reverse image on the punch guarantees that the final, molded output displays the intended text or numbers in a readable form.

12. Tablet Punch

Tablet punches and dies often referred to as tablet tooling, punch and die sets, or compression tools play a critical role in tablet manufacturing. Using high-quality tooling isn’t just recommended; it’s essential for ensuring consistent performance, boosting productivity, and extending the lifespan of the tools themselves.

These tools directly influence key aspects of the final product, including the tablet’s size, shape, imprint, and weight. Typically, punches and dies are installed in a tablet press machine, which can be either a single-punch press or a rotary press, depending on the scale and type of production.

Here’s how the process works: granulated powder is fed into a cavity that’s formed by the die and two punches one at the top and one at the bottom. Once the powder is in place, the upper and lower punches come together and apply pressure from both sides.

This force compresses the material inside the die cavity, shaping it into a solid tablet. The effectiveness of this compression depends heavily on the precision and quality of the punches and dies involved.

FAQs

What is a punch tool used for?

A punch is a tool used to indent or create a hole through a hard surface. They usually consist of a hard metal rod with a narrow tip at one end and a broad flat “butt” at the other.

What is an example of a punch tool?

A few of the basic types include center punch, prick punch, pin punch, and drift punch. Workshops use punches for locating centers for drawing circles, punch holes in sheet metals, start holes for drilling, remove damaged rivets, bolts, or pins, and transfer the location of holes in patterns.

What is a punch tool before drilling?

A center punch tool is a special type of punch tool that’s used to create a shallow indention in a workpiece for the purpose of drilling. Prior to drilling a hole in a workpiece, a worker may use a center punch tool to “mark” the area of the workpiece where the drill bit will enter.

What are punch down tools used for?

A punch down tool, which can also be named an RJ45 punch down tool, or Krone tool, is a hand tool widely used to terminate the Ethernet cables by inserting the cable wires into the insulation-displacement connectors (IDC) on the punch down blocks, patch panels, keystone modules, and surface mount of boxes.

What to use instead of a punch down tool?

I went through lots of my tools and landed on a T8 (torx 8) screwdriver type tool. This tool fits perfectly into the punch connectors on the patchbay without bending or damaging the connector and you can get one for a few bucks at the local hardware store.

What is a knockout punch tool used for?

In metalworking, a knockout punch, also known as a chassis punch, panel punch, Greenlee punch, or a Q-max, is a hand tool used to punch a hole through sheet metal. It is a very simple tool that consists of a punch, die, and screw. There are three different drive systems: manual, ratchet, and hydraulic.