Swager dies are essential elements of the swaging process, which is a high-production, high-precision metal forming process.

Swaging is not machining – it doesn’t remove material – it forms the shape of the metal (typically a rod, tube or wire), with a series of rapid compressive blows. The benefits of swaging are from the high material efficiency, increased strength ( because of grain flow), and great finish.

Swager dies are the pieces that interact with the workpiece to achieve the desired geometry and sizes.

How Do Swager Dies Work?

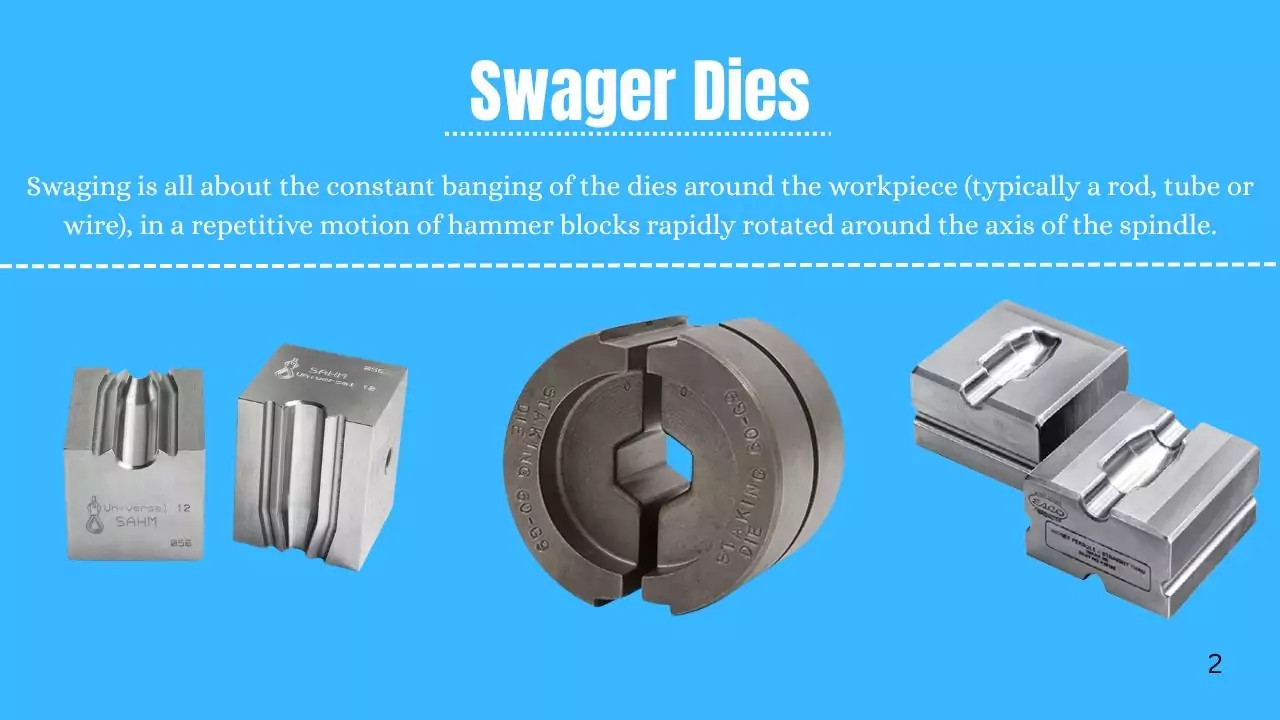

Swaging is all about the constant banging of the dies around the workpiece (typically a rod, tube or wire), in a repetitive motion of hammer blocks rapidly rotated around the axis of the spindle.

Each impact against the workpiece is a cause of the metal to flow plastically, or minimizing the cross-sectional area, tapering the workpiece, or forming certain profiles.

A hot swaging process, and cold swaging process can be accommodated easily, but most of the time would be done cold, being a popular choice because of work hardening and good surface finish.

Swager dies would be mounted at the center of a swaging machine, either a rotating spindle or housing to hold the die will be determined by a swager on how it was designed.

A rotating swaging machine is one of the most common swaging machines available on the market, which uses the hammer blocks to hold the swager dies in place.

Due to the effect of centrifugal forces through rotation, the hammer blocks with the dies are indicated outward toward a series of rollers encircling the spindle.

Each time that the hammer blocks strike against one of the rollers, they drive the hammer blocks inward against the workpiece’s die closing the die and compressing the metal workpiece.

This rapid sequence of opening or closing thousands of times per minute, progressively shapes the material.

To prevent longitudinal burrs from forming along the seam created by the swaging dies, either a rotational relative motion of the dies to the workpiece exists or the workpiece moves rotationally between the dies.

Types of Swager Dies

Swager dies are a fundamental piece of equipment for many manufacturing processes.

Swager dies are classified by their bore geometry, application and swaging machine type. These classifications allow for a targeted swaging method, from a simple reduction in diameter to a complex forming or attachment task.

#1. Cylindrical Swaging Dies (Straight Bore Dies).

Cylindrical swaging dies (or straight bore dies) are the most frequently used type of die because of their simple nature of having a uniform cylindrical bore of a constant diameter throughout the length.

Straight bore dies typically obtain a uniform reduction of an entire workpiece’s diameter during the swaging operation.

Variations of straight bore dies are available to suit their intended purposes; a Type R straight bore die is as it sounds with a true straight cylindrical bore, and a Type A straight bore die has rounding on one side suitable for a specific end-forming application.

Some cylindrical dies have cutting edges suitable for crimping or cutting aluminum or copper ferrules cleanly.

Other dies have no cutting edges and these dies are preferred for use with steel and stainless steel ferrules when there is not a desire to impact force of the swaging die and induce cursing action.

These adjustable dies can be utilized to achieve a uniform reduction of wires, rods, and tubes and to attach ferrules to wire wires.

#2. Conical Swaging Dies (Tapering Dies).

Conical swaging dies, or tapering dies, are identified by their tapering bore that allows for a gradual, conical bore, diameter reduction.

This design is important for developing a pointed or tapered end. These dies are standardly referred to as Type K. A variation of this type is known as Type KH. The Type KH dies include a pin in the conical bore.

This pin forms an inspection hole in the swaged piece which is important for all swages as an inspection hole, especially in safety-sensitive applications such as wire rope assemblies, as it supplies evidence of a good swage, or one that has not failed due to movement by the swage.

Conical dies are essential when pointing tubes, rods, and wires, often as a prelude to subsequent redrawing operations, and are important when creating tapered components to be used in many things from furniture legs, sporting items and aeronautics parts etc.

#3. Multi-Stage Swaging Dies.

When the desired geometry is multi-faceted or there is significant diameter reduction achieved through several stages, employers will rely on multi-stage swaging dies.

Multi-stage swaging dies are designed with several geometries in a continuous bore, allowing for a multi-stage reduction process to create the complex geometries the swaging die is designed to shape.

Type FR refers to cylindrical multi-stage swaging dies, which is designed to achieve a series of cylindrical reductions. A variant is Type FRK which also achieves the same multi-stage cylindrical swaging but is devoted for shorter, limited applications.

Utilizing these multi-staged dies is mandatory when consistent dimensional control is critical during the swaging operation allowing designers to create very specific components with a high degree of fidelity.

#4. Open Channel Dies.

Open channel dies are different from the other dies in that they have an “open channel,” shape which for swaging several different types of sleeves made out of stainless steel, Duplex, and single materials.

They can accommodate select sizes of sockets with carbon steel sleeves. Open channel dies are typically used in wire rope rigging businesses where they swage different types of ferrules and sleeves on to cables.

#5. Ferrule Dies.

Ferrule dies are designed for the sole purpose of swaging ferrules (or sleeves) on to wire ropes to form a safe and permanent attachment. Their shape varies in accordance to the way the ferrule is inserted and swaged.

Straight-through channel dies allow for swaging of an infinite number of ferrules through a channel type swaging operation.

The straight channel is a good option for High Volume applications; for example, swaging ferrules for large shares of being tree farms. However, for heavy volume applications Ferrule dies offer an effective swaging method.

Front entry dies mean that the ferrules can only be swaged at the end of a rope.

Ferrule dies have great importance when making strong mechanical splices for wire rope assemblies in many different industries high lifting, construction, marine, and infrastructure.

#6. Staging Dies.

Staging dies are designed to swage larger sockets. One significant feature of staging dies if the “cutaway ends” that allow for a very close swage of the socket and wire rope or cable.

The cutaway is especially useful if you are lifting heavy loads in rigging and lifting applications. Large diameter cables and sockets are often utilized for rigging cuts and swaging dies will provide maximum strength, safety and simple operation.

#7. Forged Socket Dies.

Forged socket dies look very similar to open channel dies, with the exception that they are specifically designed to swage only forged sockets.

The diameters and length of the block are specifically engineered to fit the exact sizes of forged swage sockets.

These dies are mainly used to attach forged sockets to wire ropes or cables and especially to handle the rigors of high lifting, large weights, and to make an absolute dependable connection during high repetition structural applications.

Materials Used for Swager Dies

Due to the high levels of compressive force and repeated impacts that swager dies should be subject to, high quality, durable materials, mainly special tool steels, are used to manufacture swager dies.

The special tool steels are typically fully hardened and precision machined to deliver the right performance and longevity selected. The die bores are often polished as well to encourage easy flow and to prevent sticking of the material during swaging.

Manufacturers promote the use of very good and, often recycled, steel in the making of their dies to provide the best performance with durability and longevity.

Applications of Swager Dies

The swaging process can be used in order to manufacture complex manufacturing components due to the versatility of the process and the level of elucidate sophistication shown in the manufacture and use of swager dies. These components are applicable in different areas:

- Automotive: Dynamically produced as cold forming if automotive components, i .e. steering columns, drive shafts and other tubular automotive components.

- Aerospace: Aerospace tube components are produced in aerospace tube, fluid control tubes and other tubinul supplier store chain function especially when dimensional tolerance and accurate weight can be less.

- Medical Devices: Production of Hypodermic tubing, surgical instruments and any other small, complex assembleable components needing an absolute hold a dimension with ensured finish needs.

- Ammunition Manufacturing: Swaging can be used to form bullets at room temperature, while allowing precise diameter, specification, measurement per bullet while delivering consistency per shot.

- Fittings and Fasteners: Joining fittings to pipes, cables (wire ropes), or other assemblies by deforming the fitting such that there is a permanent, solid joint. This also includes plumbing fittings like “swage nipples” or “reducing nipples.”

- Furniture: Tapering metal tubing (for furniture legs) to increase strength and make them look better.

- Sawmills: Swages used to flare saw teeth, increasing kerf (width of the cut), improving efficiency and life of the saw blade.

- Electronics: Pressing connector pins into PCB’s, as an alternative or complement to soldering.

- General Industrial: Pointing, sizing, reducing, or forming various rods, tubes, and wires for redraw while creating some tapers.

Advantages of Swaging (and the Role of Swager Dies)

The advantages of swager dies used in the swaging process can be significant.

- Material Saving (Chipless Forming): Swaging, which is a reshaping of material without removing it, produces little or no material loss. This is especially valuable when using costly and precious metals.

- Enhanced Material Properties: The cold working process of swaging hardens the material, increasing tensile strength, hardness, and fatigue resistance. the grain structure of the material is refined, increasing the quality of the final product.

- Superior Surface Finish: Swaged surfaces are even and smooth, and often as ground surfaces (no more finishing) as well as smooth surfaces or other surfaces ready for welding rivet or similar secondary processes.

- High Precision (Tight Tolerances): The accurately sized dies which drive precise tapering allow for parts with precision and tight tolerances to be manufactured.

- Higher Production Rate: Swaging can be a very fast process, reducing cycle and processing times in some cases compared to other metal forming processes.

- Flexibility: Variety of shapes that can be formed by swaging can be very extensive from circular, to conical shapes, to even non-circular, like square and hexagonal forms depending on the die and type of machine used.

Disadvantages and Considerations

Advantages notwithstanding swaging with swager dies has some disadvantages and limitations.

- Cost of Tooling: Swager dies may be more expensive than some of the tooling of some other metal forming processes, especially swaging complex custom shapes.

- Operator Skill: To achieve the best results sometimes a more experienced operator may be required, particularly for our complicated or involved applications.

- Limited Axial Movement: The primary forming action is radial. This can limit the shapes and features to be produced in the axial direction without applying specialized processes or operations.

- Die Damage: As with most processes involving huge forces and repetitive impact, dies can wear, crack, or gall if operated outside of the parameters specified or with lack of maintenance or lubrication.

- Lubrication: Proper lubrication of the faces and cavities of the die is incredibly important as lubrication minimizes friction not only will extend die life.

Conclusion

Swager dies are an important tool in a numerous aspects of the manufacturing industry, providing the means for the efficient and precise reshaping of different metals.

Using a rapid compressive action, a product can be created that has a high strength-to-weight ratio with consideration of dimensional tolerances and aesthetics for a component for use in automotive, aerospace, medical, consumer goods, etc.

Having an understanding of what swager dies do, the types of swager dies and their operation, advantages of swaging, is important to appreciate the role they play in modern day manufacturing.

References:

- Fenn Torin. (n.d.). Swaging Machines | Swager Dies. https://www.fenn-torin.com/metal-forming-machines/swagers

- SLS Machinery. (n.d.). What Is A Rotary Swaging Machine & What Is It Used For?. https://www.slsmachinery.com/What-Is-A-Rotary-Swaging-Machine-What-Is-It-Used-For-id49031466.html

- MachineryHost. (n.d.). Rotary Swaging. https://f.machineryhost.com/c37f36800219dcb5960c40d1d4bade55/282777e0d143f575017f0849f7dd63e3/rotary_swaging-pdf

- FENN Metal Forming Machinery. (2020, March 20). Different Types of Swaging Machines. https://www.fenn-torin.com/blog/different-types-of-swaging-machines

- SAHM SPLICE. (n.d.). Swaging dies “Rounded”. https://www.sahm-splice.com/products/tools-accessories/swaging-dies/swaging-dies-rounded/

- Techniswage. (n.d.). Rotary Swaging. https://techniswage.co.uk/rotary-swaging/

- Carter Bearings. (n.d.). Staking vs Swaging. https://www.carterbearings.co.uk/technical/technical-articles/staking-vs-swaging/

- Talurit®. (n.d.). Swaging Die Sets from the market leader. https://www.talurit.com/premium/swagers/swager-die-set/

- Taylor & Francis. (n.d.). Swaging – Knowledge and References. https://taylorandfrancis.com/knowledge/Engineering_and_technology/Mechanical_engineering/Swaging/

- The Crosby Group. (n.d.). NATIONAL SWAGING MACHINE AND DIE WARNING, USE, MAINTENANCE AND APPLICATION INFORMATION. http://www.thecrosbygroup.com/html/en-US/pdf/pgs/65_72.pdf