What is Bending Stress?

Bending stress refers to the internal resistance that develops within a structural element when subjected to an external bending moment or force. As a result of this applied moment, the component bends, creating a curvature that causes some areas to experience tension while others are put under compression; these are collectively known as bending stresses.

The analysis of bending stress relies on two main assumptions: first, that any cross-section of the member remains plane after bending (often called the plane section assumption), and second, that the material behaves in a linear elastic manner, meaning the relationship between normal stress and strain follows Hooke’s Law.

It is important to note that bending stress within a beam does not distribute evenly across the entire cross-section. The highest stresses develop at the surfaces furthest from the neutral axis—the imaginary line running along the length of the beam where the stress is zero.

A solid grasp of bending stress is vital for assessing the strength and durability of structures. If the bending stresses become too great, they can lead to permanent deformation, structural failure, or even collapse. This is why a deep understanding of how bending and normal stresses operate is crucial for engineers and designers aiming to prevent failure in their designs.

The study of mechanics of materials, which explores how various materials react under different loading conditions, forms the backbone for understanding bending stress. This knowledge is essential when selecting materials and devising structural solutions that can reliably withstand the demands of bending, ultimately supporting the safety and integrity of engineered systems.

Types Of Bending Stress

The principal stresses produced by bending are the normal stresses, specifically tension and compression. However, it is important to recognize that the internal stress state of a beam is more complex; in addition to these major normal stresses, shear stresses also arise as a result of shear forces acting within the beam.

While these shear stresses are typically less significant in magnitude compared to the bending-induced normal stresses, they should not be overlooked.

When we refer to “bending stress,” we are actually talking about a collection of related stress types. Understanding these distinctions can provide a clearer picture of what a beam truly experiences during bending.

#1. Pure Bending

In the case of pure bending, an object is subjected solely to a bending moment resulting from an external force, without the influence of additional stresses such as shear, axial loads, or torsion. For pure bending to occur, certain conditions must be met, most importantly, the shear stress across the section must be zero.

While this scenario is somewhat idealized and less common in practical situations, it provides engineers with valuable insight into how a material or structure will behave when exposed exclusively to bending forces.

#2. Symmetric Bending

This scenario arises when both the cross-section of the beam and the neutral axis are symmetrical. In such cases, the force or stress distributes uniformly, leading to symmetric bending.

While this is considered an ideal case, much like the concept of pure bending, it is important to recognize that actual conditions in the field rarely align perfectly with these assumptions.

#3. Unsymmetric Bending

When considering the principles of symmetric bending, it becomes clear that unsymmetric bending arises in cases where either the cross-section of a beam or the beam itself lacks symmetry.

In such situations, the resulting stresses do not distribute evenly across the structure. Instead, this asymmetry leads to a more complex, uneven pattern of bending stress.

#4. Non-Uniform Bending

In everyday situations, conditions are rarely ideal, and as a result, non-uniform bending often occurs. This form of bending stress arises when loads are distributed unevenly across a structure and is typically accompanied by shear stress.

Realistically, this is the scenario most engineers and designers encounter, since bridges and other structures in the real world are constantly subjected to a complex mix of forces, stresses, and tensions, not just the simplified cases we might see in textbooks.

How To Calculate Bending Stress?

Now that the concept of bending stress is clear, let’s turn our attention to how it’s actually calculated. The main formula you’ll need is:

σ = M × c / I

where:

- σ represents the bending stress (measured in pascals, or newtons per square meter) at a point located a distance c from the neutral axis.

- M stands for the bending moment applied to the beam, given in newton-meters (N·m).

- c is the perpendicular distance from the neutral axis to the point where you’re measuring the stress, in meters.

- I denotes the area moment of inertia, which has units of meters to the fourth power (m⁴).

The bending moment, M, comes from loads that act perpendicularly to the beam, causing it to bend. For example, if you place a downward force of 10 N right at the center of a 3-meter beam, the resulting bending moment at the center will be 10 N × 3 m / 2, which equals 15 N·m.

To figure out c, you first need to identify the neutral axis of the beam’s cross-section. For beams that are symmetrical both vertically and horizontally, the neutral axis runs right through the center—specifically, at half the beam’s height.

The position of the neutral axis aligns with the centroid of the cross-section. Once you’ve pinpointed the neutral axis, you can measure the distance from it to any point above or below and label that as yₚ when analyzing vertical loads.

For beams experiencing horizontal loads (leading to sideways deflection), we use xₚ for the horizontal distance from the neutral axis.

If you’re after the maximum bending stress, you’ll want to use the largest possible value of c. In practice, that’s the distance from the neutral axis to the farthest edge of the beam—either the top or bottom, depending on which is farther.

If you need to look up formulas for the neutral axis of standard steel beam shapes, resources like a section modulus calculator can be very helpful.

In this discussion, the focus is on vertical deflection, so the variable of interest is yₚ. For those who need guidance on calculating beam deflections under various loads, there are dedicated tools like a beam deflection calculator.

The area moment of inertia, I, depends on the beam’s cross-section. For a simple rectangular beam, the formula is:

I = (b × d³) / 12

where:

- I is the area moment of inertia (in m⁴),

- b is the width (or breadth) of the beam in meters,

- d is the height (or depth) in meters.

There are also plenty of formulas available for other cross-sectional shapes, and a section modulus calculator can be handy for those as well. If you’re interested in a deeper dive into the moment of inertia, there are tools focused solely on that topic.

The bending stress equation can also be written using the section modulus, S, as follows:

σ = M / S

Here, the section modulus S is simply the ratio of I to c:

S = I / c

It’s important to always check that your units match up, or at least be familiar with dimensional analysis, to avoid mistakes in your calculations.

And if you want to skip the manual process, a bending stress calculator can help you work through the numbers—a topic that will be covered in more detail in the next section.

Examples Of Ending Stress

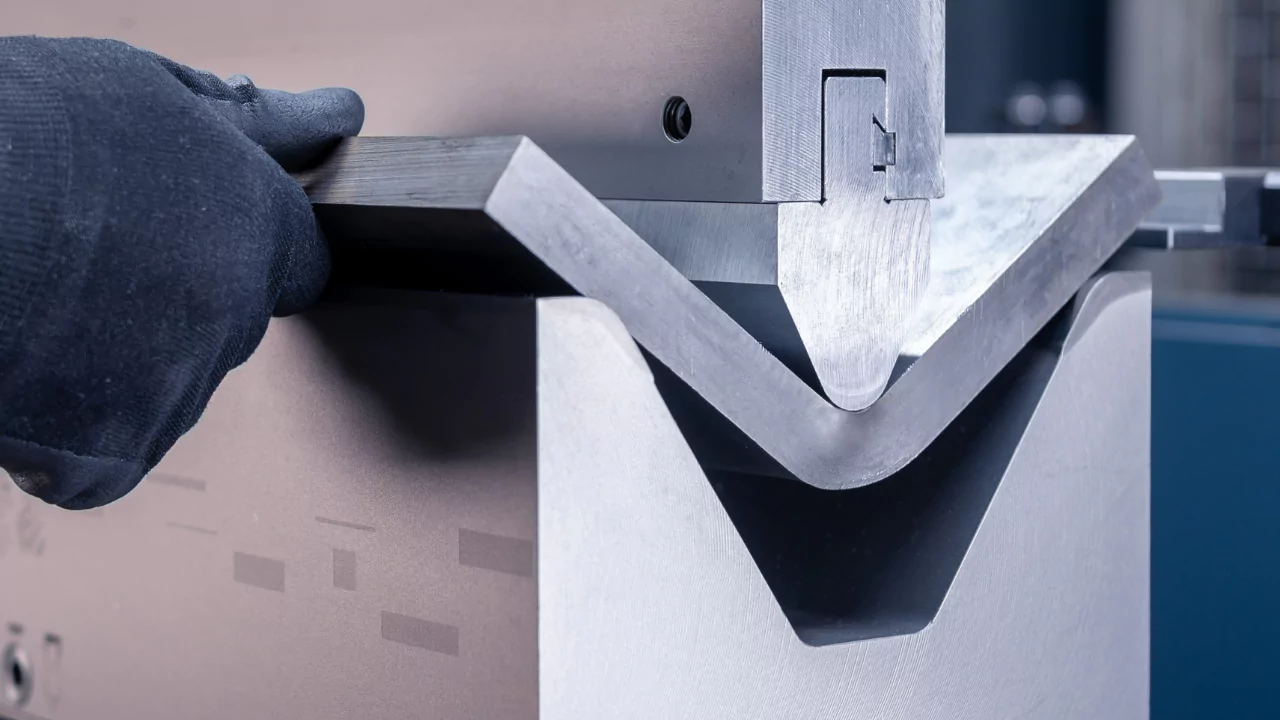

Beam bending is perhaps one of the most frequently encountered cases when discussing bending stress analysis. By definition, a beam refers to any structural element with a uniform cross-section throughout its length.

Typically, the length of a beam far exceeds the dimensions of its cross-section, which makes it possible to apply certain simplifying assumptions with reasonable accuracy.

We encounter bending stress in a wide variety of everyday items and structural systems. Just to name a few, you can spot its effects in numerous objects and constructions around us.

#1. Bridges.

When you observe the constant flow of pedestrians, pets, cyclists, vehicles, and passengers moving across a bridge, it becomes clear just how much bending stress is at play. Bridges truly illustrate what beams and structural elements experience when they are supporting real, everyday loads.

#2. Airplane wings.

Aircraft wings offer a clear illustration of bending stress in practice. The interplay between gravity and aerodynamic forces places significant demands on the wings, making the consideration of bending stress essential during the design process. To ensure reliable performance, especially when these forces are acting, engineers must carefully address how the wings will handle such stress.

#3. Buildings and architectural structures.

Engineers need to consider bending stress when designing beams and columns for structures such as skyscrapers, office buildings, and houses. This understanding is essential for determining the amount of force and the weight these structural elements can safely support.

Practical Applications of Bending Stress

Grasping the concept of bending stress is not merely theoretical; it has clear, practical significance across a range of disciplines. In civil engineering, for example, a sound understanding of bending stress underpins the analysis and design of structural components such as beams, bridges, and foundations. Without this knowledge, ensuring the safety and reliability of these structures would be nearly impossible.

Similarly, in the realm of mechanical engineering, recognizing how bending moments affect components like shafts, gears, and pulleys is fundamental to their effective design. Whether you’re developing machinery or troubleshooting failures, the ability to evaluate bending stress is indispensable.

Applications extend beyond traditional engineering as well. Take the human femur—assessing the bending stress it experiences plays a pivotal role in prosthetic design and even in anticipating the risk of fractures.

So, whether you are focused on infrastructure, machinery, or biomedical challenges, a solid command of bending stress forms a crucial part of your academic foundation and your future professional work.