What Is Gas Tungsten Arc Welding (GTAW)?

Gas tungsten arc welding (GTAW), also known as tungsten inert gas (TIG) welding, is an arc welding process that uses a non-consumable tungsten electrode to produce the weld. The weld area and electrode are protected from oxidation or other atmospheric contamination by an inert shielding gas (argon or helium).

Filler metal is normally used, though some welds, known as autogenous welds, or fusion welds do not require it. When helium is used, this is known as heliarc welding. A constant-current welding power supply produces electrical energy, which is conducted across the arc through a column of highly ionized gas and metal vapors known as plasma.

GTAW is most commonly used to weld thin sections of stainless steel and non-ferrous metals such as aluminum, magnesium, and copper alloys. The process grants the operator greater control over the weld than competing processes such as shielded metal arc welding and gas metal arc welding, allowing for stronger, higher-quality welds.

However, GTAW is comparatively more complex and difficult to master, and furthermore, it is significantly slower than most other welding techniques. A related process, plasma arc welding, uses a slightly different welding torch to create a more focused welding arc and as a result, is often automated.

How Does A Gas Tungsten Arc Welding Work?

Manual gas tungsten arc welding is a relatively difficult welding method, due to the coordination required by the welder.

Similar to torch welding, GTAW normally requires two hands, since most applications require that the welder manually feed a filler metal into the weld area with one hand while manipulating the welding torch in the other.

Maintaining a short arc length, while preventing contact between the electrode and the workpiece, is also important.

To strike the welding arc, a high-frequency generator (similar to a Tesla coil) provides an electric spark. This spark is a conductive path for the welding current through the shielding gas and allows the arc to be initiated while the electrode and the workpiece are separated, typically about 1.5–3 mm (0.06–0.12 in) apart.

Once the arc is struck, the welder moves the torch in a small circle to create a welding pool, the size of which depends on the size of the electrode and the amount of current.

While maintaining a constant separation between the electrode and the workpiece, the operator then moves the torch back slightly and tilts it backward about 10–15 degrees from vertical. Filler metal is added manually to the front end of the weld pool as it is needed.

Welders often develop a technique of rapidly alternating between moving the torch forward (to advance the weld pool) and adding filler metal. The filler rod is withdrawn from the weld pool each time the electrode advances, but it is always kept inside the gas shield to prevent oxidation of its surface and contamination of the weld.

Filler rods composed of metals with a low melting temperature, such as aluminum, require that the operator maintain some distance from the arc while staying inside the gas shield. If held too close to the arc, the filler rod can melt before it makes contact with the weld puddle.

As the weld nears completion, the arc current is often gradually reduced to allow the weld crater to solidify and prevent the formation of crater cracks at the end of the weld.

Shielding gas use in Gas Tungsten Arc Welding

Shielding gas is selected according to the material being welded. The following guidelines may help:

- Argon: the most commonly used shielding gas that can be used for welding a wide range of materials including steel, stainless steel, aluminum, and titanium.

- Argon + 2 to 5% H2: the addition of hydrogen to argon will make the gas slightly, assisting the production of cleaner-looking welds without surface oxidation. As the arc is hotter and more constricted, it permits higher welding speeds. Disadvantages include the risk of hydrogen cracking in carbon steels and weld metal porosity in aluminum alloys.

- Helium and helium/argon mixtures: adding helium to argon will raise the temperature of the arc. This promotes higher welding speeds and deeper weld penetration. The disadvantages of using helium or a helium/argon mixture are the high cost of gas and the difficulty in starting the arc.

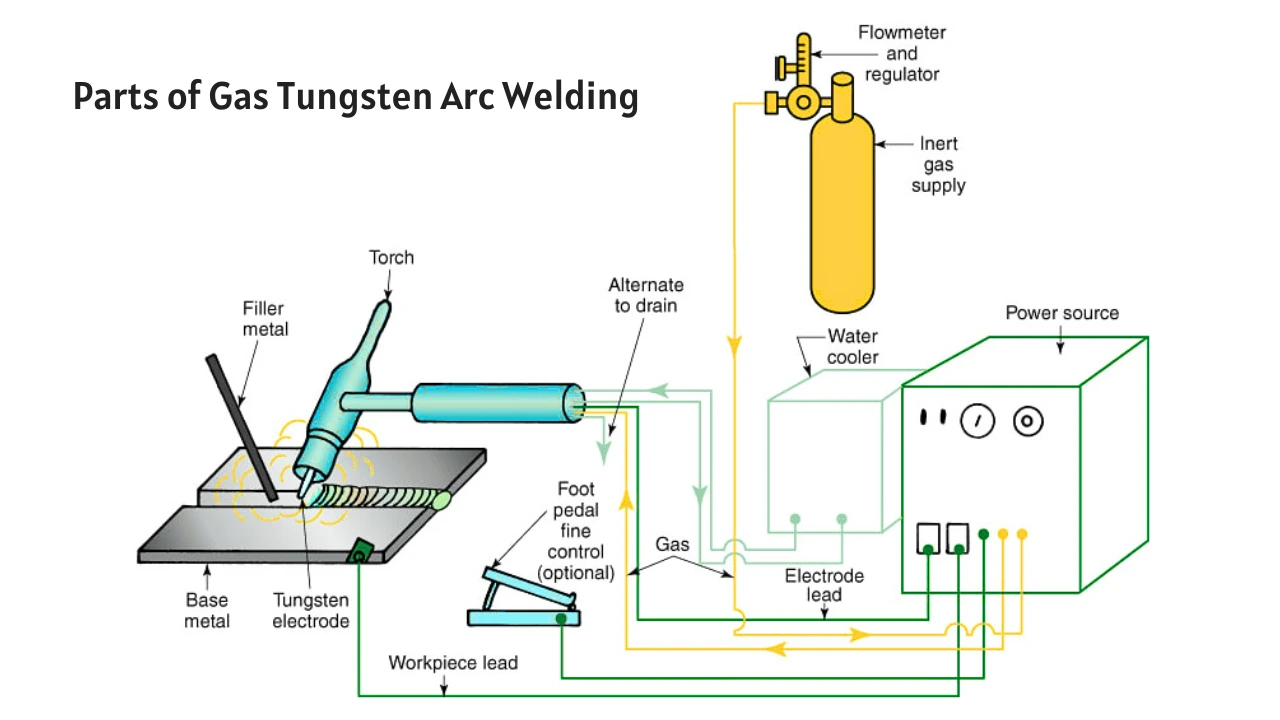

Construction Or Parts of Gas Tungsten Arc Welding

A Tungsten Inert Gas Welding Machine consists of the following equipment:

- Power Supply

- Inert Gas Supply

- Welding Torch/Holder

- Tungsten Electrode

- Shielding Gas

- Filler Rod

1. Power Supply:

In TIG welding we need a constant power supply because if there was a fluctuation of current then it is hard for the welder to weld the joints properly.

The power supply can be two types:

- DC Power Supply

- AC Power Supply

In the DC power supply, we can weld steels, nickel, titanium, etc. And in AC power supply, we can weld magnesium, aluminum, etc. materials.

2. Inert Gas Supply:

In TIG Welding, we need an inert gas supply to provide the shielding to the weld area from the atmospheric gas (For example, Oxygen, Nitrogen, and Hydrogen).

In general, Argon is used as an Inert gas supply in TIG Welding. We will discuss this later in the Shielding gas section.

3. Welding Torch:

In TIG Welding the welding torch is designed to do either automatic or manual operations. However, in terms of construction, both are the same, in the manual torch, they are provided with a handle to hold, and in the case of the automatic, they are designed to mount on an automatic machine.

Torches are provided with a cooling system either by water or air.

When the Ampere of the current is less than 200 A generally, we use air-cooling, but if it exceeds 200 A then we use water cooling to decrease the temperature of the welding torch.

The inside portion of the welding torch is generally made of copper to increase the conductivity of heat.

And the torches are provided with a holding arrangement (Port) to hold the Tungsten electrode firmly.

4. Tungsten Electrode:

In TIG Welding we use a non-consumable electrode made of Tungsten or Tungsten Alloy.

Due to the High-temperature resisting capacity (the Melting Temp of Tungsten is 3,422 °C) of tungsten rather than any other metal, that’s why we use the tungsten electrode.

The diameter of the electrode is generally varying from 0.5 mm to 0.65 mm, and the length varies between 75 mm to 610 mm.

5. Shielding Gas:

Shielding gases are used to protect the welding pool from atmospheric gases like nitrogen, and oxygen otherwise these gases can damage the welding surface by creating porosity, blowhole, etc.

Choosing Shielding gases depends on the types of welding as well as the atmospheric condition the type of metal used for the operation and many more.

However, generally, we use Argon as a shielding gas in TIG Welding. Sometimes Argon-helium mixtures are also used in this type of welding.

6. Filler Rod:

As we already know, in TIG Welding, we use a non-consumable electrode that is Tungsten, so in some cases, we need separate material to fill up the gap between two joints.

The material of the filler rod can be anything, like carbon steel, aluminum, etc. It generally depends on the type of joints, the work-piece material, thickness, and also the properties of the workpiece.

Applications of Gas Tungsten Arc Welding

- This is specially used in the welding of refractory, sheet, and reactive materials.

- Tungsten Gas welding can be used with such a large variety of metals, the process can be applied to several industries and aid in the creation and repair of many items. This form of welding is common in the aerospace, automotive, repair, and art fields.

- Aerospace: Aircraft and spacecraft are constructed in part by means of TIG welding.

- Automotive: Safe and secure construction is essential in the auto industry, as is making vehicles stand the test of time.

- Repair: TIG may be used in a number of repair applications. From fixing a child’s toy, like a wagon or old-fashioned pedal car, to repairing aluminum tools, this welding method comes in handy.

Advantages of Gas Tungsten Arc Welding

The advantages of Tungsten Inert Gas Welding are the following:

- Tungsten welding offers a solution for welding critical joints, and for situations where small or exceptionally precise welds are required.

- It can be performed with a wide variety of metals

- And, when done correctly, it produces a high-quality and high-purity weld compared with other joining processes, which is crucial in many applications.

- It can be done both automatically and manually.

- Overall, it is one of the most efficient ways to join two metals.

- No slag is produced.

- TIG Welding can be done in any position.

Disadvantages of Gas Tungsten Arc Welding

The disadvantages of TIG Welding are mentioned below:

- Tungsten welding cannot be used for thicker sheets of metal.

- More complicated Skilled and professional workers are needed.

- The safety issue, welders are exposed to the high intensity of lights which can cause eye damage.

- The price of TIG welding services is high. However, costs will vary depending on the materials being welded, and the scope of the project.

- It is a slow process of welding.