Fasteners are essential components in the fabrication of the many materials that make up everyday items. If you have ever been involved in a DIY project, you likely used some type of fasteners to help you get the job done.

At All Points Fasteners we are excited about the important role quality fasteners can play for homeowners and professionals. Before we get too far, let’s define fasteners and discuss some of the different types, as well as their uses.

What Is a Fastener?

To begin, we need to clarify what a fastener actually is. Fasteners is a broad category, and encompasses tools like screws, nuts, and bolts, which all act to mechanically hold objects together.

Sure, things like glue hold objects together, but glue isn’t a fastener. So we have to expand our definition. Hardware fasteners mechanically hold objects together.

Fasteners are usually a non-permanent joint. In other words, when you connect two items with a fastener, you can remove it, and the two items should come apart with minimal (if any) damage to the engineering or the fabrication.

An example of the opposite situation would be a welded joint, for instance, as a destination joint formed by a fastener, except for rivets when looking at fasteners, will be permanently joined.

So, although the majority of fasteners will join a non-permanent joint, this certainly does not mean that you should only use fasteners when you know you want to take something apart, and it does not mean the joint is weak in any fashion.

Yes, a fastener can mechanically hold together objects which can endure a high level of stress. So, fasteners are an excellent option to create a permanent joint as well as a non-permanent one, which comes in handy for the way you want to use it in your project.

The Most Common Types of Fasteners

Mechanical fasteners come in different types. Each of those types also has many subtypes that you can choose from. Among the different types of fasteners, here are the most common ones:

- Bolts: These are fasteners that hold two unknown parts together(no threads). These are the most common.

- Screws: Screws, for many people, are what they think of first when they think of fasteners. Screw fasteners are one of the most versatile fasteners available. Their threaded shaft gives them durable holding power and unlike a bolt, they don’t need something to hold them in place. In general, you drill a pilot hold in the material and then use a screwdriver to drive it in place. Screws come in many different types and sizes.

- Nuts: A nut has an internal thread and works with bolts to hold components together.

- Washers: They are small circular discs as an annulus. They are used along with nuts and bolts and have important fastening function.

- Nails: Nails have been used since antiquity and they are still in a majority of households. You can distinguish the difference between a screw or a nail, the nail is defined by not having any threads. While it doesn’t have the effective holding power a screw has, it has greater shear strength making it a better application choice.

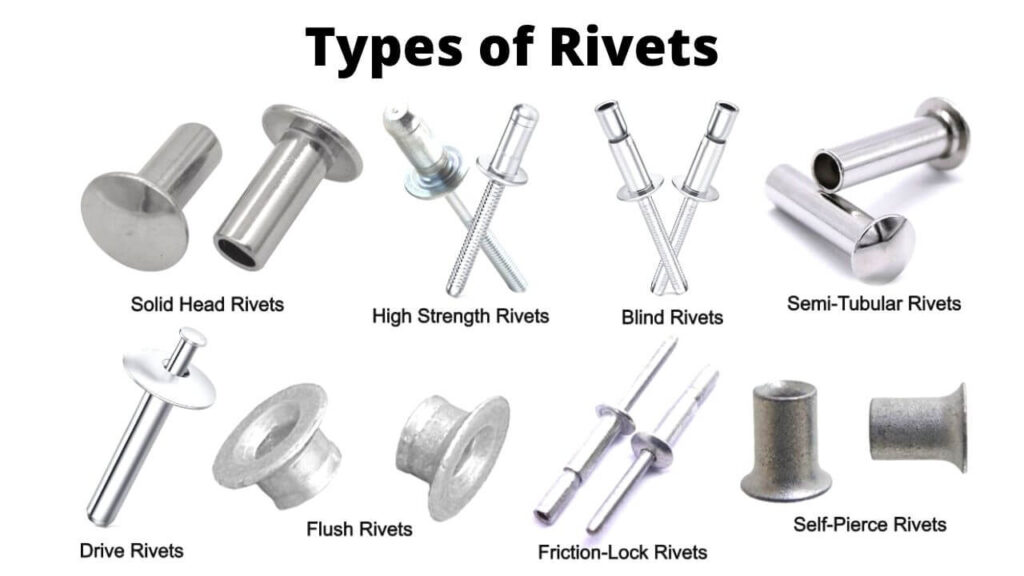

- Rivets: Rivets are a class of permanent fastener that aids in securing various components.

- Anchors: Anchors get their name because they serve similar functions as a boat anchor embeds into the seabed and prevents the movement of a ship. In general, people use anchors to affix something to a material like drywall or concrete. They embed themselves to the material to hold the objects being affixed in place.

Types of Screws

1. Deck Screws

Long screws are typically utilized to fasten deck boards. Deck screws will have a type 17 point (notched point at tip) to assist with removing wood chips during the thread cutting process, ensuring proper installation in wood and composite deck materials. The bugle head and square drive help eliminate some of the stripping effect created by other types of drives.

2. Hex Lag Screws

Lag screws can also be referred to as lag bolts, and since they are considered a fairly large wood screw, they have a hex head which is driven with a wrench.

This type of screw can be used for lagging (that is attaching) lumber together for framing purposes, attaching machinery to wood flooring and heavy-duty applications.

3. Self-Drilling Screws

Self-drilling screws include a sheet metal thread with a self-driller cutting (TEK) point that enables it to pierce through a variety of metals ranging from 20 to 14-gauge. The TEK number increases with the size of the drill point that can pierce heavier gauge metals.

4. Sheet Metal Screws

Sheet metal screws (SMS) are screws that have sharp cutting threads cut into sheet metal, plastic, or wood. Sheet metal screws usually have a completely threaded shank, and may have a notched point at the end of the screw to facilitate the removal of chips when cutting the threads.

5. Wood Screws

Wood screws have deep cutting threads with a long smooth shank. They’re manufactured to let the screw slide through the top piece of wood and tightly pull all pieces of wood together.

6. Concrete screw

Stainless or carbon steel and used for fastening materials to concrete.

7. Masonry screw

Often have a blue coating and are inserted to a pilot hole in masonry.

8. Double-ended (dowel) screw

Have two pointed ends and no head. Often used for making hidden joints between two pieces of timber.

9. Drive screw

Smooth, round, or mushroom-headed with a reduced diameter shank.

10. Drywall screw

Often coated with black phosphate and designed with a bugle head. Used to attach drywall to timber or metal studs.

11. Eyebolt

A looped head is designed to be used as an attachment point. Also used for attaching wires across building surfaces.

12. Lag screw/bolt

A heavy-duty fastener.

13. Chipboard screw

Often wax-coated and used for fastening down chipboard flooring.

14. Mirror screw

Designed with a decorative dome or another cover to conceal the head.

15. Twinfast screw

Designed with two threads that enable it to drive twice as fast.

16. Security head screw

Designed with a head that is impossible to reverse, making it suitable for security applications.

Related Post: 35 Different Types of Screws and Their Uses

Types of Rivets

1. POP Rivets (Open-End)

POP Rivets, which can also be referred to as blind rivets, are used to join two materials together in a rapid and efficient manner. POP Rivets are tubes with a hat and a mandrel, when installed, you break off a portion of the mandrel.

2. Closed-End POP Rivets (Sealed)

Closed-End Rivets are distinguished from a standard blind pop rivet because they have a closed-off end that forms a watertight seal.

3. Large Flange POP Rivets

Large Flange also referred to as Oversize, pop rivets have a larger washer on the hat than regular POP Rivets. Also called blind rivets, they are used to join two pieces of material quickly and easily when needing to connect two materials.

Large flange POP Rivets are a type of tubular rivet that consists of a hat and mandrel, and the length of the mandral is broken off during installation.

4. Countersunk POP Rivets

Countersunk, or Flat, POP Rivets, are utilized to join two materials together, quickly and efficiently. The hat of the rivet is nearly inverted, having a 120 degree countersink in the integrated washer.

POP Rivets are tubular, the hat and mandrel being separate pieces; the mandrel breaks off when it is installed.

5. Colored Rivets

When talking about colored rivets, we are referring to open-end pop rivets, also known as colored open-end pop rivets. Colored rivets are about painted rivets.

The hat of the rivet is painted either brown, black, or white. The colors are designated in order to either hide rivets for a finished look, or to make them more visible with the opposite color from the install material.

6. Multi-Grip Rivets

Multi grip rivets are commonly used to replace standard rivets when the thickness of the materials being installed can vary. The rivet simply expands to the size (within its own limits), and holds both materials together.

7. Structural Rivets

Structural rivets can result in a more robust assembly involving a lot more force and require a different tool to install than a stainless-steel pop rivet.

8. Tri-Fold Rivets

Tri-Fold rivets, also known as bursting rivets, have three slits cut in the hat that allows it to fold outward when fastened into three separate wings. A Unity rivet has improved strength and holding power than regular pop rivets.

Types of Washers

1. Backup Rivet Washers

The use of rivet backup washers is to create a larger install diameter, allowing the rivet a better hold and more support. Backup washers also can help to prevent the pull through of a rivet.

2. Belleville Conical Washers

Belleville conical washer is a kind of washer that adds additional tension to a fastener assembly. Belleville conical washers are used in a stack for greater load, deflection, or both to an assembly depending on the stack. Belleville conical washers can also be considered a lock washer since they add tension and absorb vibration to an assembly.

3. Dock Washers

Dock washers are heavy-duty washers often used to build docks. Used for heavy-duty construction where a thick washer may be preferred. Dock washers have a fender washer configuration means they have a smaller inside diameter and hole.

4. Fender Washers

Fender washers are circular washers with a small inside diameter hole. Fender washers prevent pull-through and provide a larger bearing surface under the fastener.

5. Fender Washers – Extra Thick

Fender washers are circular washers with a small inside diameter hole. Extra thick fender washers are thicker than standard fender washers. Extra thick fender washers are used to prevent pull through and provide a larger bearing surface under the fastener.

6. Finishing Cup Washers

Finishing cup washers have a shape that allows them to fit a cup for the head of the screw or fastener to fit in. This creates a flush finish with the head of the screw or fastener. Finishing cup washers are for finishing purposes, since they are cup shaped.

7. Flat Washers

A flat washer is a circular outer diameter, thin plate, with a punched center hole sized to the fastener. Flat washers are used to spread the load of threaded bolts, screws, or nuts, evenly as the fastener is tightened.

8. Flat Washers – Extra Thick

Extra thick flat washers tend to be thicker than the average flat washers. They are round outer diameter thin plates, with a center hole punched to the size of the bolt or screw being used. Flat washers distribute the load of the threaded bolt, screws, and nuts even as the fastener is turned to tighten it.

9. Flat Washers – Military Standard

Military standard (MS) flat washers are inspected extensively for the chemical, physical, and dimensional properties. MS washers must fulfill rigorous inner and outer diameter requirements.

10. Flat Washers – 900 Series

The 900 series flat washers are round and thinner than the standard flat washers. 900 series flat washers have a smaller inside diameter and a smaller outside diameter.

11. Lock Washers – Split Ring

Split ring lock washers are intended to act against the potential of nuts, bolts, and screws from vibrating loose. These washers are rings that split at one location and bent into a helical shape.

12. Lock Washers – High Collar

High collar lock washers fit under the cap screw head and prevent nut and bolt vibration using split ring lock washers. Split ring lock washers are rings with one point that is split and bent to a helix.

13. Lock Washers – External Tooth

External tooth lock washers are utilized for locking and tensioning. Round washers with teeth on the outside are used for maximum holding power. Tobe used with fasteners with an acceptable head size.

14. Lock Washers – Internal Tooth

Internal tooth lock washers serve a purpose in locking and tensioning applications. With internal teeth it is a circular washer constructed to prevent a nut or screw head from loosening with the strut action of the teeth.

15. NAS Washers

NAS washers are round washers that have a smaller inner and outer diameter and are typically used in military specifications due to strict tolerances for measurements.

16. Neoprene EPDM Washers

These are round washers that are beveled slightly at the edges and have a neoprene lining. Mostly used with sharp-point self-drilling TEK screws to create a watertight seal around the screw and/or metal roofing or siding.

17. Structural Washers

Structural washers are rugged, heavy-duty washers designed particularly for structural applications. Examples of these heavy-duty washers include all structural assembly washers that are utilized in construction, such as Steel Beams and girders as fasteners.

18. Square Washers

Square washers are square-shaped washers that may be flat on both sides, or one side flat and the other side beveled. Square washers are commonly used with square head bolts. Square washers will prevent pull-through and offer a greater surface area and increased holding capacity than round flat washers.

Related Posts: Different Types of Washers for Bolts And How They Use?

Types of Concrete Anchors

1. Acoustical Wedge Anchors

Anchors for masonry acoustical wedge are designed to anchor and secure suspended wire to masonry materials such as solid or block masonry etc.. The anchor is inserted into the pre-drill hole and then hammered which extends the wedge to hold the anchor in place.

2. Drop in Anchors

Drop-in anchors are internally threaded anchors that are generally hanging overhead and flush with the surface of the concrete. These are used to build handrails, lighting fixtures, and numerous other fixtures. Drop-in anchors require the use of a setting tool to install.

3. Double Expansion Shield Anchors

Double expansion shield anchors can be installed in low quality or soft materials. There is expansion through the entire length of the anchor in the hole, which creates a very strong grip. This expansion relies on friction and also holds the installation material.

4. Hammer Drive Pin Anchors

These anchors are intended for lighter-duty applications in comparison to other kinds of concrete anchors. Drive pins attach a fixture to masonry materials.

A hammer is driven into the exposed head of the drive pin. The hammer drives the pin into the masonry until it expands the base inside of the masonry material and makes a hold.

5. Kaptoggle Hollow Wall Anchors

Kaptoggle hollow wall anchors are installed by being pushed through a hole in the wall or block surface via its wings, and further, a supplied machine screw is tightened into the threads creating a secure hold when tightening.

Kaptoggle wall anchors have been shown to have greater holding power and predictability than typical types of hollow wall fasteners.

6. Lag Shield Expansion Anchors

These anchors are expansion anchors that are covered and used to hold lag screws. They are designed to expand outward when lag screws are driven into them. The expansion pushes against the surface that is installed on creating a snug secure hold.

These too have relatively extremely accurate internal threading to allow the installation lag bolt to turn freely.

7. Machine Screw Anchors

Machine screw anchors are placed into masonry materials into a pre-drilled hole. Once in the hole, a machine screw is threaded into the anchor and tightened. The process of tightening the machine screw pulls the coned portion into the sleeve making it deform.

The deformation of the sleeve makes a tight wedge in the hole making it difficult to take out easily.

8. Masonry Screws

Concrete masonry anchors, commonly referred to as Tapcons, cut threads into concrete, brick, or block in installation. The blue climaseal coating provides extra corrosion protection. No pre-drilling with spot holes or inserts are required.

9. Plastic Toggle Anchors

Plastic toggle anchors are used in hollow walls or cinder blocks to create a fastening point for sheet metal screws. The toggle anchors have legs that can be folded for entry into a pre-drilled hole that expands when a screw is driven into them. Once the legs are deployed, the toggle anchor is securely in place.

10. Sammy’s Screws

Sammy Screws are used with threaded rods and will save time in drilling into masonry, since they will drill holes into masonry materials. (The design of a Sammy Screw has a female threaded portion to accept the threaded rod into it.)

Any Sammy can be installed in a horizontal or vertical position, and they are widely used because they are inexpensive to install, flexible (for a range of repairs), and simple to use.

11. Sleeve Anchors

Concrete masonry sleeve anchors are shaped like a threaded stud with a cone-shaped end that flares outward, the stud has a nut and a washer on the end.

When you tighten the nut, it pulls the stud end into the sleeve expander, wedging it outwardly and locking the anchor in place with the base material. Made specifically for hollow concrete applications (i.e. cinderblocks).

12. Toggle Wing Hollow Wall Anchors

Toggle Wings are effective when installation is accomplished by field-installing through a material. The wing can be bent to half its length and pushed through the material.

Once it has passed through and into the stud it will expand, and then can be screwed into to fasten secure against the back of the material you are using.

13. Wedge Anchors

Concrete masonry wedge anchors are intended to fasten and secure material and equipment to solid concrete masonry surfaces (ex. concrete slabs). Composed of an anchor, a nut, and a washer. Used to fasten concrete to equipment, materials, generators, motors, pumps, pipe, strut, plastics, and wood.

FAQs

What are 7 types of fasteners?

Fasteners are hardware devices used to mechanically join or secure two or more objects together. There are numerous types of fasteners, including screws, bolts, nuts, washers, rivets, pins, clips, and anchors, among others.

What are 5 types of permanent fasteners?

Fasteners used for carpentry, construction, DIY, and marine applications. They come in a wide range of types, and each type in a wide variety of designs. Types of permanent fasteners include bolts, nuts, rivets, staples, and adhesives.

What is the most common fastener?

Screw fasteners are the most commonly used type of fasteners. They are highly versatile and durable. These socket screws have to fix eroded internal threads spanning across their whole length and their heads come in various shapes. Screws require internal threads in objects for holding them together.

What are the five basic fasteners?

Let’s look at each of these common examples of fasteners and break them down a bit further.

1. Screws.

2. Nails.

3. Bolts, Nuts and Washers.

4. Anchors.

5. Rivets.

What are Grade 8 fasteners?

In the U.S., a Grade 8 fastener is made of medium carbon alloy steel, quenched and tempered, and has a tensile strength of at least 150,000 psi. These fasteners are designated as Grade 8 because they meet or exceed the minimum tensile strength requirements for this grade as outlined in the SAE J429 standard.