What is Flux-Cored Arc Welding (FCAW or FCA)?

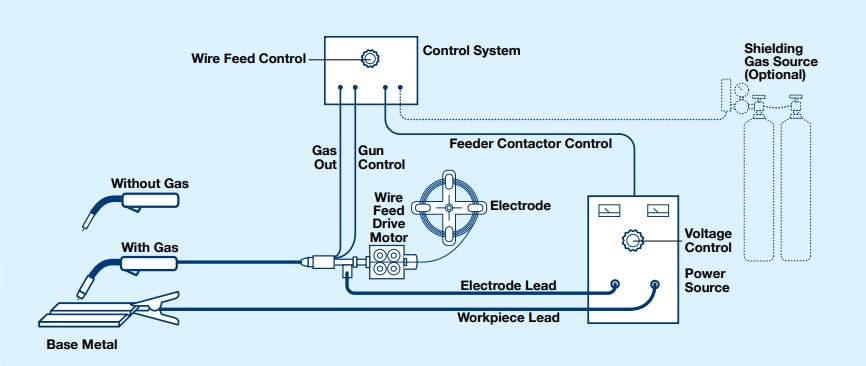

Flux-cored arc welding (FCAW or FCA) is a semi-automatic or automatic arc welding process. In this process, a continuously fed consumable tubular electrode containing a flux is used, as well as either a constant-voltage or, less frequently, a constant-current power supply.

An externally supplied shielding gas is sometimes used, but more often than not, the flux itself is expected to provide the necessary atmospheric protection, producing both gaseous protection to protect the weld and liquid slag on the weld. FCAW is often used in construction because of the speed of welding and the ease of transport.

Flux-cored arc welding (FCAW), more commonly known as dual shield welding, is a semi-automatic arc welding process that is considered somewhat similar to metal active gas (MAG) welding.

FCAW uses the same basic equipment as MAG welding, including a continuous wire-fed electrode fed from a spool, a constant-voltage welding power supply, and a similar welding technique.

Flux core arc-welding initiated in the 1950s as an alternative for Manual Metal Arc (MMA) welding (also known as stick welding). FCAW has helped to resolve many of the limitations of MMA, as it uses a continuously fed wire electrode.

Flux core arc-welding generally uses a shielding gas, much like MAG welding. FCAW can, however, operate without shielding gas. Furthermore, FCAW is usually more productive than MAG welding.

How Does Flux Core Arc Welding Work?

Flux cored arc welding utilizes heat developed by an electric arc to fuse the base metal in the weld joint area. The arc is struck between the metallic workpiece and the continuously-fed tubular cored consumable filler wire, in which both the wire and the metallic workpiece are melted to produce a weld joint.

This process is similar to MAG welding except that FCAW welding utilizes a hollow tubular electrode filled with flux instead of a solid metal electrode.

There can be two separate types of FCAW depending on the shielding; one where the process has a shielding gas externally supplied, and one that solely utilizes the flux core itself for shielding the weld area.

The shielding gas, where supplied, protects the weld pool from oxidation and is typically supplied from a high-pressure gas cylinder aimed at the weld zone.

The weld metal is also shielded by the slag formation due to the melting of the flux. Therefore, FCAW is commonly referred to as ‘dual shield’ welding and was initially designed for structural steels.

The most common shielding gases are carbon dioxide or a mixture of argon and carbon dioxide. The most common mix used is 75% argon and 25% carbon dioxide. The dual shield method is especially effective for welding thicker material or for out-of-position welding.

In this process, as long as both operate in the same conditions, welds can be produced with more consistent mechanical properties with less defects than produce from the MMA or MAG processes. The continuously fed tubular electrode permits much higher production rates than the same operation with solid wire or stick electrodes.

However, the gas shielded method will not be successful in windy conditions since disturbance to the gas shielding may lead to loss of weld metal properties.

The second version of the process is where shielding gas is not supplied externally, but is only produced by the flux-cored electrode. The flux-cored electrode produces gaseous protection and produces a slag that copiously covers and protects the molten metal in the weld.

The filler wire core is filled with fluxing agents that produces slag and certain materials that produces shielding gases when burned by the arc of the welding arc.

Because the flux provides shielding gas, this means this process may be used for outdoor applications in windy conditions without need for external shielding gas. This adds to the process versatility and suitability for outdoor welding applications.

Applications

The following are the applications of FCAW:

- This arc welding process is beneficial to shipyard operations in that it saves immense labor costs.

- It is applicable to other construction industries in the welding function.

- It is very widely used in mechanical industries.

- FCAW can be used on plain carbon, alloy, stainless and duplex steels.

- It can be used for surfacing and hard-facing.

Advantages and disadvantages of flux-cored arc welding (FCAW)

Advantages

Flux cored arc welding is advantageous for many applications. Flux cored arc welding usually competes against shielded metal arc welding, gas metal arc welding, and submerged arc welding for many applications. Some of the advantages of flux cored arc welding are:

- It has high deposition rates and increased travel speeds can be employed.

- Welding can be performed in the all-welding positions using small diameter electrode wires.

- Some flux-cored wires do not use an external shielding gas which makes the equipment simple.

- The electrode wires are continuously fed, so there is very little time spent on changing the electrodes.

- A higher percentage of the filler metal is used than for shielded metal arc welding.

- Greater penetration is achieved than with shielded metal arc welding.

Disadvantages

Despite the great benefits of FCAW, some disadvantages still occur. Below are the limitations of flux cored arc welding in their various applications.

- It produces slag, which must be removed after welding

- It produces more smoke which is hazardous to the welder

- Cost of applied wire

- It Is complex and more expensive

- It produces more spatter

FAQs

What is flux-cored arc welding used for?

The flux core welding process is excellent for welding dirty, rusted, or contaminated metals. This welding process is ideal for all welding positions and outdoor welding activities because of the flux shield. The flux-cored arc welding process is quite easy to learn and master.

Is flux core welding as good as MIG welding?

Properly performed MIG welds are objectively of metallurgically higher quality than equivalent FCAW due to the gas shielding. However, it is an extraordinarily fast welding process, incredibly portable, and can produce acceptable welds in poor environments.

What are the disadvantages of flux core welding?

FCAW Disadvantages

1. A high level of noxious fumes must be ventilated.

2. Higher electrode wire cost compared to solid electrode wires.

3. More costly equipment than many other welding processes.

4. Less portable equipment than SMAW or GTAW.

5. The slag covering the weld must be removed.

Can you weld iron with flux core?

Although cast iron can be welded with the MIG process and specialised flux-cored electrode wires, the resulting welded joint won’t be as strong as with MMA arc welding. As mentioned earlier, the R-Tech team recommends MMA stick welding as first choice for welding cast iron.

Do you push or pull when flux core welding?

The flux core welding motion naturally produces slag. Therefore, it’s best to pull away from what you’ve welded. Pushing the wire will cause the flux to become trapped in the melted metal.

Do you need gas for flux core welding?

Self-shielding flux-cored wires do not require an external shielding gas. With this type of electrode, the weld pool is protected as gas is generated when the flux from the wire is burned.