What is Arc Welding?

Arc welding is a type of welding process using an electric arc to create heat to melt and join metals. A power supply creates an electric arc between a consumable or non-consumable electrode and the base material using either direct (DC) or alternating (AC) currents.

Arc welding is a prominent form of welding used across various industries, including automotive, shipbuilding, construction, and aerospace. The process entails using concentrated heat generated by an electric arc to weld metals together.

The arc occurs from the base material to the electrode, the welding rod or wire, and melts the metal. Then the welder can fuse the molten metal and craft it into a weld.

Most arc welding processes are either consumable or non-consumable electrode methods, which determines the role of the electrode, and whether it melts to become part of the weld or solely acts as an arc conductor without melting.

While many other welding processes use gas, arc welding uses electricity, with some types requiring either direct currents (DC) or alternating currents (AC). However, some types of arc welding require gas shielding to protect the arc against contaminants.

Related: What is Welding?

How Does Arc Welding Work?

Arc welding works by using an electric arc from an AC or DC power source to generate a staggering heat of around 6,500 degrees Fahrenheit at the tip, to melt the base metals, and to create a pool of molten metal and join the two pieces.

The arc is formed between the workpiece and the electrode, which is moved along the line of the joint either mechanically or manually.

The electrode can either be a rod that carries the current between the tip and the workpiece, or it can be a rod or wire that conducts current as well as melts and supplies filler metal to the joint.

Metal tends to react chemically to elements in the air such as oxygen and nitrogen when heated to extreme temperatures by the arc. This creates oxides and nitrides, which ruin the strength of the weld.

Therefore, a protective shielding gas, slag, or vapor needs to be used to lessen the contact of the molten metal with the air. After the piece has cooled, the molten metal is able to solidify to create a metallurgical bond.

DC vs. AC Currents

The electric power supply for arc welding can come from either a direct (DC) or alternating (AC) current.

Direct current (DC) arc welding is often used in stick welding and lower-voltage cases and is generally preferred over AC. This is because the DC current uses electrons that flow steadily in one direction, creating a smoother and more stable arc.

Alternating current (AC) arc welding has greater volatility in the electrons, as they change direction constantly.

AC current is usually a secondary choice in welding but can be helpful in some instances, like when a stronger current is needed to prevent the arc from blowing out or for transmitting electricity over large distances.

Types of arc welding

The different types of arc welding are roughly divided into the non-consumable electrode and consumable electrode types, as well as the arc generation and welding principles.

The electrodes (or “sticks” or “rods”) used in arc welding can be either consumable or non-consumable.

A consumable electrode not only conducts the current but also supplies filler metal to the joint. This means the electrode is made of a type of metal that melts along with the metals being welded together. This type of welding is often used in the manufacture of steel products.

A non-consumable electrode, on the other hand, is made of material that is not melted during the welding, such as tungsten, which has an extremely high melting point.

Arc Welding can be categorized into two different types;

| Electrode consumption | Welding method |

| Non-consumable (non-fusible) electrode type | 1. TIG welding 2. Plasma welding |

| Consumable (fusible) electrode type | 1. Shielded metal arc welding 2. MAG welding 3. MIG welding 4. Electrogas arc welding (EGW) |

Consumable Electrode Methods

There are different types of arc welding. Which arc welding method you use depends mostly on the metal. Following is an overview of various kinds of arc welding techniques:

MIG Welding

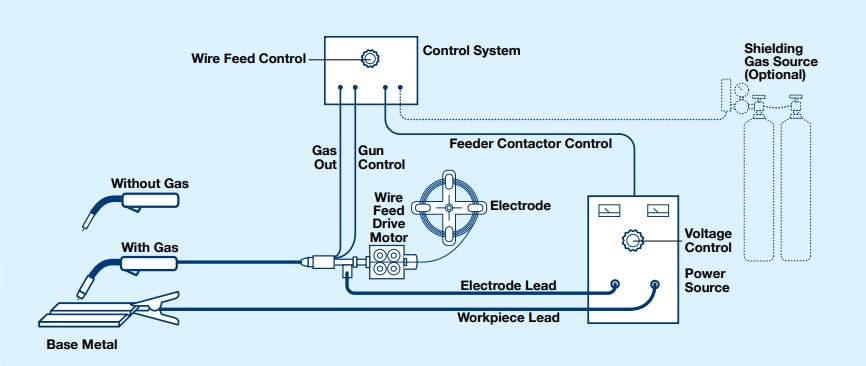

Also known as Gas Metal Arc Welding (GMAW), uses a shielding gas to protect the base metals from contamination.

GMAW or MIG welding shields the arc with a gas like argon helium or a gas mix. The electrodes have deoxidizers that prevent oxidation, so you can weld multiple layers.

This method has several benefits: simple, versatile, economical, low temperatures, and easily automated. This is a popular welding technique for thin sheets and sections.

Shielded metal arc welding (SMAW)

SMAW is one of the simplest, oldest, and most adaptable arc welding methods, making it very popular. The arc is generated when the coated electrode tip touches the welding area and is then withdrawn to maintain the arc.

The heat melts the tip, coating, and metal so that the weld is formed once that alloy solidifies. This technique is typically used in pipeline work, shipbuilding, and construction.

Flux-cored arc welding (FCAW)

This type of arc welding uses tubular electrodes filled with flux. While emissive flux shields the arc from the air, non-missive fluxes may need shielding gases.

It is ideal for welding dense sections that are an inch or thicker because FCAW has a higher weld-metal deposition rate.

Submerged arc welding (SAW)

SAW works with a granular flux that creates a thick layer during welding, which completely covers the molten metal and prevents sparks and spatters.

This method enables deeper heat penetration because it acts as a thermal insulator. SAW is sued for high-speed sheet or plate steel welding. It can be semiautomatic or automatic. However, it is limited to horizontal welds.

Electro-Slag Welding (ESW)

ESW is a welding process that uses heat which is generated by an electric current moving between the consumable electrode and the workpiece. This creates a molten slag, which covers the weld surface.

The molten slag’s resistance to the passage of the electric current creates heat for melting the wire and plate edges. The metal solidifies as it is hit with water. This is a vertical process that is used to weld thick plates that are above 25 mm in a single pass.

Non-consumable Electrode Methods

TIG Welding

GTAW or TIG welding is often considered to be the most difficult. Tungsten electrodes create the arc. Inert gases like argon or helium or a mix of the two are used to protect the shield.

Filler wires add molten material if needed. This method is much “cleaner” as it doesn’t produce slag, making it ideal for welding jobs where appearance matters as well as thin materials.

Plasma arc welding (PAW)

Similar to TIG, PAW uses an electric arc between a non-consumable electrode and an anode, which are placed within the body of the torch.

The electric arc is used to ionise the gas in the torch and create the plasma, which is then pushed through a fine borehole in the anode to reach the base plate. In this way, the plasma is separated from the shielding gas.

Carbon Arc Welding

The carbon arc welding (CAW) process is the oldest of all the arc welding processes and it is the beginning of arc welding. An electric arc forms between a non-consumable carbon electrode and the workpiece, joining the metals and creating a solid bond.

No shielding is used. Pressure and filler metal may or may not be added. It has limited applications today, but a variation or twin carbon arc welding is more popular. Another variation uses compressed air to force molten metal out to effect cutting.

Where Is Arc Welding Used?

Arc welding is commonly used to join materials and is used across a lot of different industries.

The aerospace industry uses arc welding to manufacture and repair aircraft, join sheeting, and for precision work. The automotive industry uses arc welding to bond exhaust systems and hydraulic lines. Arc welding can deliver extremely strong bonds even between thin metals.

The construction industry uses arc welding to guarantee strong, sustainable connections within buildings, bridges, and other infrastructures. Other industries that use arc welding are the oil and gas industry and the power industry.

Rod Types

The arc process uses a variety of rods that have different strengths, weaknesses, and uses which can impact weld quality. The rod is connected to the welding machine and a current is passed through to join workpieces together.

In some cases, such as with SMAW, the rods melt to become part of the weld – these are consumable electrodes. In other instances, such as with TIG, the rods do not melt – these are non-consumable electrodes.

Rods are generally coated, although the exact type of coating varies. While uncoated rods are available, these are far less common, create more spatter, and can make it difficult to control the arc.

Coated rods are better to reduce or eliminate contaminating oxides or Sulphur. The three types of coating include cellulose and minerals. or a combination of the two.

Whether coated or uncoated, the correct rod needs to be selected to create clean, strong welds with the right bead quality.

Application of arc welding

The applications of Arc Welding include the following.

- Used in the welding of sheet metals

- For welding thin, ferrous & non-ferrous metals

- Used to design pressure & pressure vessels

- The developments of piping in industries

- Used in the domains of automotive and home furnishing

- Industries of Shipbuilding

- Used in the manufacture of aircraft & aerospace, Auto body restorations, and Railroads.

- Industries like construction, automotive, mechanical, etc.

- Gas Tungsten Arc Welding is used in aerospace industries to connect many areas like sheet metals.

- These weldings are used for repairing dies, tools, and mostly on metals that are made with magnesium & aluminum.

- Most of the fabrication industries use GTAW to weld thin workpieces, particularly nonferrous metals.

- GTAW welding is used where extreme resistance to corrosion as well as cracking over a long period of quality are required.

- It is used in space vehicle manufacturing.

- Used to weld small-diameter parts, and thin wall tubing, making it applicable in bicycle industries.

Advantages of arc welding

There are a number of advantages to using arc welding compared with many other formats:

- It is suitable for high-speed welds.

- It is a simple welding apparatus.

- It can work on AC or DC.

- Superior temperatures.

- Less smoke or sparks are involved.

- Portability as a result of the simple equipment.

- It is a fast-welding process when compared to others,

- It offers strong joints.

- Produces very little distortion.

- High corrosion resistance.

- It has the ability to weld on porous and dirty metal.

- It is the equipment that is inexpensive.

- Its operation can be performed during wind or rain.

- Its power supply can be used where there is electricity and the alternative can use be if there is no electricity but generators.

- Smooth welding is achieved.

- It is a good impact strength.

- Arc welding beads can be used to create designs on fine metals.

- It can be carried out in any atmosphere.

Disadvantages of arc welding

There are a few reasons why some people look to other options beyond arc welding for certain kinds of projects. These downsides can include:

- Require skilled welders.

- Cannot be used for reactive metals like AI or Ti.

- Not suitable for welding thin metals.

- Not all thin metal can weld on arc welding.

- A well-trained and skillful operator is needed for the task.

- Increases in project costs as wastage is inevitable during the process.

FAQs.

What is Arc Welding?

Arc welding is a welding process used to join metal to metal by using electricity to generate enough heat to melt metal and the melted metals, when cooled, resulting in a bond of the metals. It is a type of welding that uses a welding power supply to create an arc between a metal stick (“electrode”) and the base material to melt the metals at the point of contact. Arc welders can use either direct current (DC) or alternating current (AC) and consumable or non-consumable electrodes.

How hot is a welding arc?

Arc welding is a fusion welding process used to join metals. An electric arc from an AC or DC power supply creates an intense heat of around 6500°F which melts the metal at the join between two work pieces.

When was arc welding invented?

In 1890, C.L. Coffin of Detroit was awarded the first U.S. patent for an arc welding process using a metal electrode. This was the first record of the metal melted from the electrode carried across the arc to deposit filler metal in the joint to make a weld.

What is arc welding used for?

Arc welding is commonly used to join materials and is used across a lot of different industries. The aerospace industry uses arc welding to manufacture and repair aircraft, join sheeting, and for precision work. The automotive industry uses arc welding to bond exhaust systems and hydraulic lines.

How does arc welding work?

Arc welding works by using an electric arc from an AC or DC power source to generate a staggering heat around 6,500 degrees Fahrenheit at the tip, to melt the base metals, and to create a pool of molten metal and join the two pieces.