Lathe Machine Operations

A lathe is a versatile machine tool designed to rotate a workpiece along its axis, allowing users to perform a wide range of operations everything from cutting and facing to knurling and even reshaping materials.

You’ll often see lathe machines at the heart of metal spinning, thermal spraying, woodturning, and general metalworking. These aren’t just fancy words; they represent the real, hands-on tasks that keep workshops humming.

When you’re working with a lathe, the list of possible operations is pretty extensive. Grooving, turning, cutting, grinding, and sanding are just a few examples that come up regularly in practice.

But before you even think about firing up the machine, there’s some homework to do: understanding feed rates, cutting speeds, depth of cut, and the correct way to use each tool.

Each operation has its own quirks and requirements, so taking time to learn these basics isn’t just academic—it’s practical and essential for anyone wanting good results.

It’s easy to underestimate how important these factors are, but getting them right makes all the difference. Proper attention to speed, feed, and depth is what separates smooth, precise work from a botched job (or, worse, a dangerous one).

Every time you make a cut, you’ll find yourself adjusting these variables, aiming for the best precision possible. That’s the real art of working with a lathe: knowing when and how to tweak things for the job at hand.

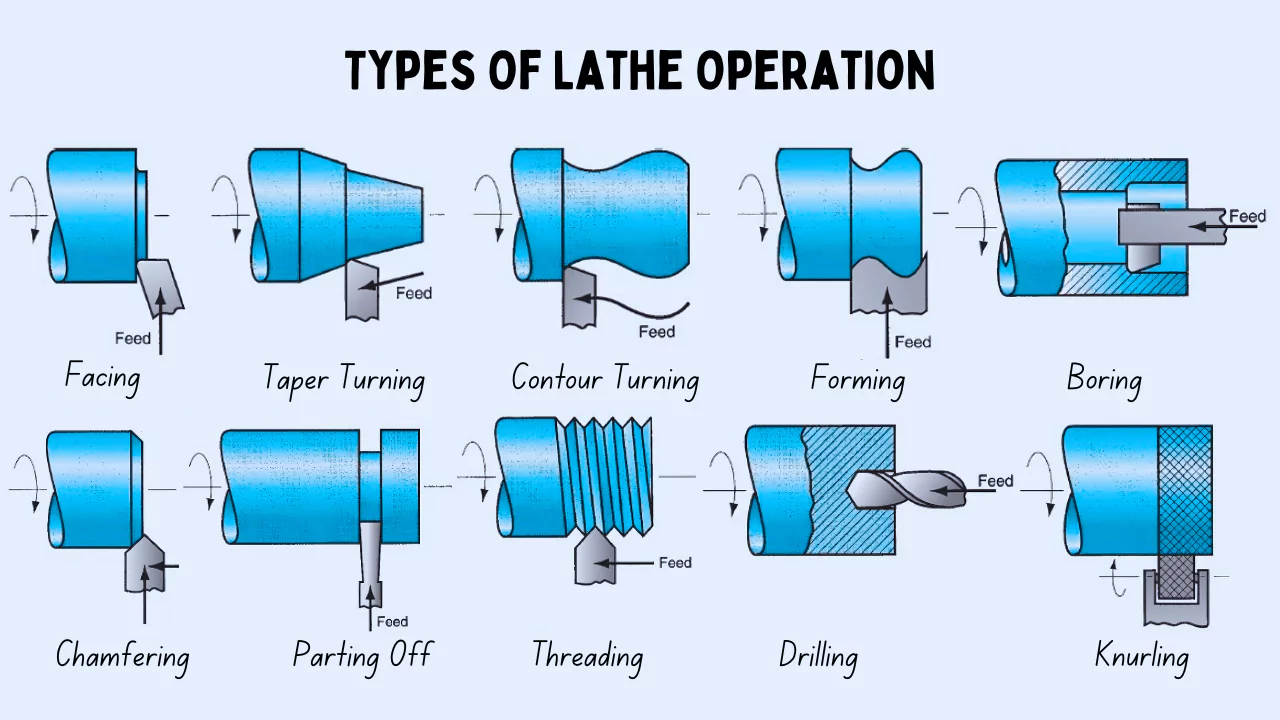

Types of Lathe Operation

The working of the lathe machine changes with every operation and cut desired. There is a lot of operations used for using the lathe machine. Some of the common lathe operations are:

- Facing: Let’s start with facing, which is typically the first step you’ll tackle on a lathe. In this process, the metal’s end is carefully trimmed so it’s perfectly square with the axis, and any surface marks from previous handling or cutting get cleaned up in the process.

- Tapering: Tapering is what you do when you want the workpiece to transition into a cone shape. The compound slide on the lathe makes this possible, sitting somewhere between straightforward parallel turning and simple facing. If you need a specific angle, you just adjust the compound slide to match what you’re after.

- Parting: Parting is all about separating a finished section from the rest of the material. Here, the parting tool is introduced gently into the work. For deeper cuts, you’ll back out the tool a bit and shift it sideways, which not only gets you a clean cut but also helps protect the tool from snapping.

- Parallel Turning: Whenever the goal is to reduce the diameter of a part, parallel turning is the go-to technique. The cutting tool moves parallel to the workpiece’s axis, shaving material evenly along its length.

- Contour Turning: Contour turning breaks away from the straight-and-narrow. Instead of following a direct path, the cutting tool is guided along a specific curve or contour, giving the finished piece a unique profile. The feed here isn’t parallel to the axis but follows the shape you want.

- Rough Turning: When you need to remove a lot of material quickly, rough turning comes into play. This is a high-feed, deep-cut process—think cuts between 2 to 5 mm deep, with the tool advancing at about 0.3 to 1.5 mm per revolution. The focus is on efficiency and speed.

- Form Turning: Form turning calls for a specially shaped tool, designed to create a specific profile. Unlike other methods, the tool moves radially into the workpiece, producing shapes and forms in one go.

- Chamfering: Chamfering means cutting away just the edge or corner of a cylindrical piece. It’s often used to relieve stress at sharp edges and to make parts safer and easier to handle.

- Boring: Boring involves enlarging a hole that’s already been drilled or cast. Using a single-point tool, you feed it in a straight, linear direction along the inside diameter to achieve the desired finish and size.

- Drilling: Drilling and reaming are typically handled by advancing the tool right along the axis of the spinning workpiece. The result: precise, clean holes where you need them.

- Knurling: Knurling is a bit different—it’s a forming rather than a cutting operation. By pressing a patterned roller into the metal’s surface, you create a regular, cross-hatched grip pattern. No chips, no cutting, just forming.

- Reaming: After drilling, if you need the hole to be smooth and exactly the right size, reaming is the next step. You use a tool called a reamer, which is usually mounted in the lathe’s tailstock, to gently finish the drilled hole.

- Spinning: Spinning is a chipless process for shaping sheet metal. You fix the metal between a form (called a former) and the tailstock center, then spin it at high speed. A rounded tool presses the metal so it takes on the shape of the former—almost like pottery, but with metal.

Lathe Cutting Tools

A lathe is a versatile machine tool designed to rotate a workpiece around a central axis, enabling a range of machining processes. Typical operations carried out on a lathe include turning, undercutting, knurling, drilling, facing, boring, and cutting.

These processes are accomplished by applying lathe cutting tools to the workpiece, ultimately producing objects that are symmetrical about their axis of rotation.

In most general machining tasks, single-point cutting tools are commonly used because of their adaptability. However, for more specialized operations, it is sometimes necessary to employ multipoint cutting tools, depending on the requirements of the task.

Understanding how a lathe operates is essential for anyone involved in machining. If you’re interested in seeing these operations in action, I recommend checking out the video linked below—it’s a practical way to visualize how the machine works.

It’s important to note that each lathe operation may require a specific type of cutting tool. The choice of tool depends on the particular process being performed. Here’s a breakdown of the various lathe operations and the corresponding tools used for each:

Types of Lathe Cutting Tools

There is a wide range of lathe tools that can be classified according to materials, structures and purposes or uses.

- Turning Tool: Turning tools are essential for shaping material on a lathe. When a large amount of material needs to be removed quickly, machinists rely on a rough turning tool. For those final touches—where accuracy and a smooth finish matter—a finishing turning tool comes into play, removing only a small amount to refine the workpiece.

- Boring Bar: If you’ve already got a hole drilled but need it bigger, that’s when a boring bar steps in. This tool lets you widen an existing hole efficiently, making sure it reaches the exact diameter needed for the next part to fit properly.

- Chamfering Tool: Ever noticed a beveled edge on a piece of metal? That’s called a chamfer. Chamfering tools are used to cut those angled edges, not just for looks, but to remove sharpness and make the part safer to handle.

- Knurling Tool: Knurling tools are designed to create patterns—usually cross-hatched—on round sections like handles or fasteners. This pattern isn’t just decorative; it adds grip, making it easier to hold or turn the part.

- Parting Tool: When you need to cut all the way through a piece, you use a parting tool. Think of it as a narrow blade that slices a workpiece into two, or separates a finished part from the remaining stock. There are various shapes and styles, depending on the job.

- Thread Cutting Tool: Thread cutting tools are what you turn to when you need to make screw threads, either on the outside or inside of a part. For external threads, the workpiece might spin in a chuck or sit between centers; internal threads usually mean holding the part in a chuck while the tool moves linearly, shaving off thin layers with each pass.

- Facing Tool: If you want to create a perfectly flat surface that’s perpendicular to the part’s axis, a facing tool is the way to go. It’s mounted in a holder on the lathe carriage and moves across the face of the part, producing a smooth, clean finish.

- Grooving Tool: Grooving tools, often made with carbide inserts, are designed for cutting precise slots or grooves. These inserts can have multiple tips and are ground to match the specific size and shape needed for each task.

- Forming Tool: Forming tools come in flat or circular shapes, and they’re used when you need to cut a specific groove, undercut, or thread profile. The cutting edge is shaped exactly to match the profile required.

- Shoulder Turning Tool: To create a shoulder—a step or ledge—machinists use different types of turning tools. A square shoulder usually needs a knife-edge tool, while beveled or filleted shoulders are made with tools that have specific edge angles or a rounded nose to match the desired contour.

- Counterboring Tool: When you need a stepped hole with a flat bottom (so a bolt head sits flush), a counterboring tool does the trick. This can be done with a regular boring tool, but specialized counterbores with multiple cutting edges are common for a cleaner result.

- Undercutting Tool: For cutting recesses or grooves inside a hole, undercutting tools are specially shaped to match the groove required. They’re given clearance on all sides and used with a longitudinal feed to achieve the correct profile, with the clearance angle depending on the workpiece’s diameter.

FAQs

What are the 5 major parts of the lathe machine?

The main parts of the lathe are: (1) the bed, (2) the quick-change gearbox, (3) the headstock, (4) the carriage, and (5) the tailstock.

What are the 7 operations of a lathe machine?

The variation of tool ends and a kinematic relation between the tool and workpiece results in different operations on a lathe. The most common lathe operations are turning, facing, grooving, parting, threading, drilling, boring, knurling, and tapping.

How to use a lathe machine step by step?

Starting the Machine

1. Turn on the power switch and the coolant pump.

2. Adjust the spindle speed and feed rate according to the material being machined.

3. Engage the spindle by pulling the spindle control lever towards the operator.

4. Gradually increase the speed until the desired speed is reached.

What is the depth of cut in a lathe machine?

The depth of cut parameter focuses on the tertiary cutting motion of the tool as the tool is pushed deeper into the workpiece to the specified depth. This parameter is measured as thousandths of an inch or thousandths of millimeters. The depth of cut will usually vary between 0.1 to 1.0 mm.

What are the four main units of a lathe?

A lathe consists of four main parts: the bed, spindle, turret, and tailstock. Briefly, the main spindle holds the material and rotates it.