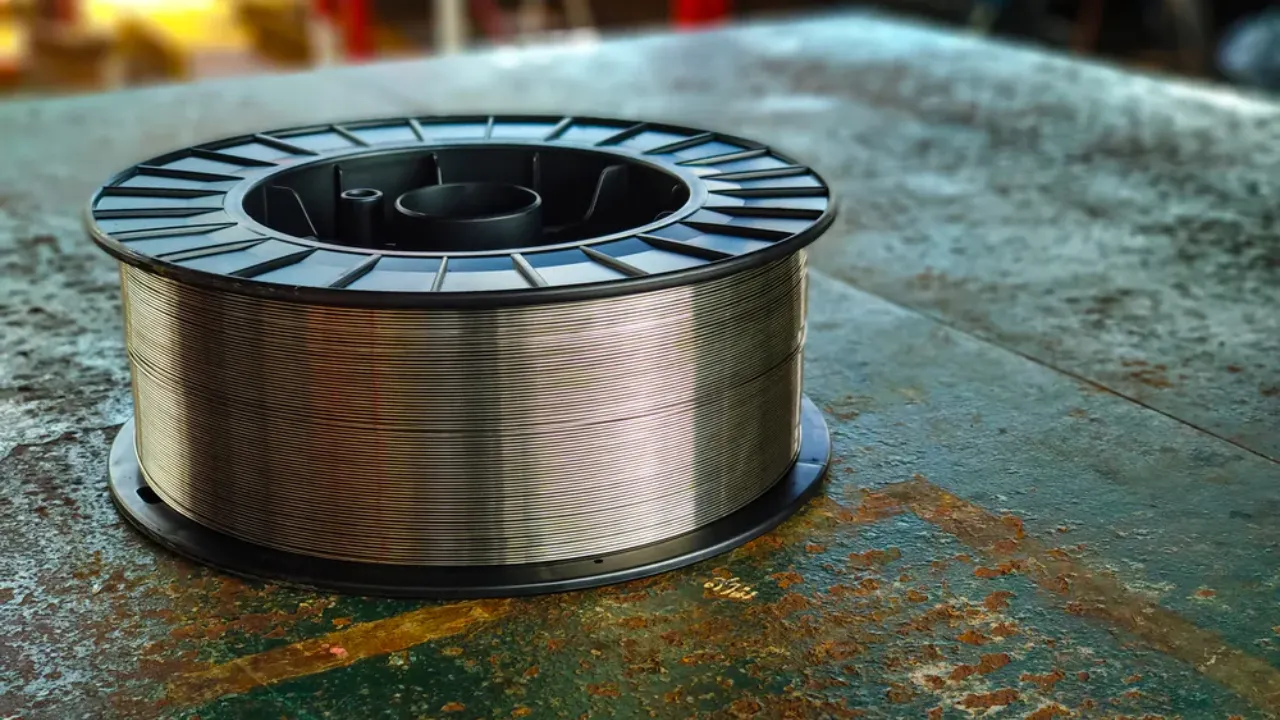

MIG welding wire consists of a spooled-up electrode that’s fed through a MIG welding “gun” and is heated to melt metal and join workpieces together. Sounds simple enough, right?

Well, it’s not quite that easy. There are a lot of different types of MIG welding wire, and in this article, we’ll explain some of the differences between them, what to consider when choosing welding wire, and the importance of choosing high-quality wire.

MIG Welding Wires

MIG (metal inert gas) wire provides filler metal for GMAW (gas metal arc welding) tasks. Also known as welding wire or filler wire, this solid wire requires external shielding gas to keep contaminants out of the weld pool.

MIG welding wires are a crucial component of MIG welding and are the consumable materials used in the welding process. These wires are made of metal, typically steel or aluminum, or they can have a copper coating and are spooled on a drum or coil. The wire is fed through a welding gun and then heated and melted by an electrical arc to join two pieces of metal together.

So instead of manually feeding the rod in TIG welding or the electrode in Stick welding, the MIG solid wire feeds automatically at the given welding speed rate. As a result, the wire fuses the two pieces of metal, enabling them to form a strong bond.

In addition, the semi-automated feeding of MIG welding wire allowed welders to complete projects much faster and with ease, which is the reason MIG welding became one of the most popular processes among hobbyists, new welders, and DIY enthusiasts.

By selecting the right type and size of wire, you can ensure that the weld is strong and free from defects. The wire also helps to protect the welder from burns by absorbing a large portion of the heat generated during the welding process. All of these factors combine to make MIG welding wires an essential part of the welding process.

Is MIG Solid Wire The Same As Flux Cored Wire?

MIG (Metal Inert Gas) Solid Wire and Flux Cored Wires are both types of welding filler material used in welding. They have similar properties: they are both made from steel, they both conduct electricity, and they are both used with a MIG welder. However, they are different in several ways.

Flux-core wire is a metal electrode that contains a “flux compound” inside the electrode. When the wire melts and reacts with the welding arc, this forms a gas that protects the weld from oxygen, which can cause defects in the weld. This means that no shielding gas is required for this type of wire – though in some cases, shielding gas may be used alongside flux-core wire for even more protection.

In contrast, solid wire electrodes are exactly what they sound like – large reels of solid metal wire that do not contain any flux. This means they must be used with a shielding gas. The most common shielding gas is 75% argon and 25% carbon dioxide. The welding gun delivers a steady stream of gas from a container, which surrounds the electrode and weld area to prevent oxidation and defects in the weld.

Depending on the application, both kinds of MIG welding wire (solid and flux-core) can be made from a variety of materials including aluminum, stainless steel, copper, and silver, to name just a few.

MIG Welding Wire Types

MIG Wires For Carbon Steel

MIG Welding carbon steel or mild steel are typically welded with an ER70s-6″ electrode using either 100% Carbon Dioxide gas or C25 gas that is 25% Carbon Dioxide and 75% Argon mixture. If you are welding a higher grade of carbon steel the minimum tensile strength is what usually changes.

For example, if you are welding high-strength steel the “ER70S-6” would be an “ER90S-6” instead. The change in the strength of the steel is what would be different.

Carbon Steel ER70S-6 Electrode Designation

The label ER70S-6 represents the following:

- ER– An electrode or filler rod that is used in either a MIG wire feed or TIG welding.

- 70– A minimum of 70,000 pounds of tensile strength per square inch of weld.

- S -Solid wire.

- 6– The amount of deoxidizing agent and cleansing agent on the electrode. This is a copper coating on the electrode and there are different types too.

MIG Wires For Stainless Steel

MIG welding stainless steel has a variety of electrodes because it is used on a wide range of projects that require different types of stainless steel grades. It is also commonly welded to Carbon steel on the same jobs.

For example, a stainless-steel brace that is welded to the building holds stainless steel piping. Here are the different types of stainless-steel electrodes. Stainless Steel is typically welded with the electrode classes and they are:

- ER308L

- ER309L

- ER316L

1. ER308L and ER308LSi

These stainless electrodes are mostly used for lower-grade stainless steel 301, 302, 304, 305, and 308. This is not the shiny stuff most people think of as stainless steel. It is typically used in industrial applications and it does get some rust spots from time to time. The picture on the left is a 304 stainless steel welded with an ER308L series wire. The wire designation is as follows:

- ER– An electrode or filler rod that is used in either a MIG wire feed or TIG welding.

- 308 – The grade of the Stainless-Steel Electrode.

- L –Low Carbon. Carbon content is what gets the rust spots on the stainless.

- Si– (Optional) Sometimes “Si” is added and that means high silicone content. Basically, it helps the weld wash into the metal better. Kind of like turning up the heat and holding the sides longer.

2. ER309L and ER309Si

The 309 series has a multi-use designation because it is used to weld stainless steel to mild or stainless to carbon or low alloy steels. It welds stainless steel grades 304 through 310 when needed or welds dissimilar metals together where needed.

The downside of using this electrode to weld steel to stainless is that the weld appearance is rough. It does the job but no matter how high you turn up the machine it feels like it is running cold. No matter what you do the welds seem to look rough compared to welding stainless steel to stainless steel.

The gas used most of the time is the same C2 or 2% carbon dioxide and 98% Argon. There are many other choices (some are better) for gas but the C2 is the most commonly used. Here is the electrode designation:

- ER– An electrode or filler rod that is used in either a MIG wire feed or TIG welding.

- 309 – The grade of the Stainless-Steel Electrode.

- L –Low Carbon.

- Si– (Optional) Sometimes “Si” is added and that means high silicone content. Basically, it helps the weld wash into the metal better. Kind of like turning up the heat and holding the sides longer.

3. ER3016L and ER316LSi

These stainless electrodes are mostly used for higher-grade stainless steel mainly in the food industries and marine applications. The base metals the ER316 welds are stainless grades 304,305, 308, 310, 312, 314, 316, 317, 321, 347, and 348.

As for gasses, C2 (2% carbon dioxide and 98% Argon) is the most widely used. There are many other mixtures to choose from and that all depends on what your welding supplier has to offer. The wire designation for the ER316L and the ER316LSI are as follows:

- ER– An electrode or filler rod that is used in either a MIG wire feed or TIG welding.

- 316– The grade of the Stainless-Steel Electrode. This is food grade and true marine grade. But nowhere the best grade of stainless.

- L –Low Carbon. Carbon content is what gets the rust spots on the stainless.

- Si– (Optional) Sometimes “Si” is added and that means high silicone content. Basically, it helps the weld wash into the metal better. Kind of like turning up the heat and holding the sides longer.

MIG Wires For Aluminum

MIG welding aluminum electrode selection is pretty straightforward. There are two typical choices and they are:

- ER4043

- ER5350

Now there are other choices but is rare to need any other electrodes. As for gas choices, it is always 100% Argon gas. If you are welding aluminum thicker than 1/2 of an inch then you may want to try an Argon Helium mix.

In most cases 100% Argon is what most shipyards, power plants, and fab shops use no matter what the thickness of the aluminum is. Here are the aluminum electrode designations:

1. ER4043

The ER4043 is the most commonly used MIG filler wire. It welds aluminum grades 2014, 3003, 3004, 4043, 5052, 6061, 6062 and 6063. It may also be used to weld cast aluminum grades 43, 214, 355, and 356.

The gas used is always 100% Argon and in rare cases, a helium/Argon mix may be used on base metals thicker than ½ of an inch. Electrode’s classification and designation are as follows:

- ER– An electrode or filler rod that is used in either a MIG wire feed or TIG welding.

- 4– The series of aluminum. This electrode is made from 4000 series aluminum.

- 043 – This number indicates the amount of silicone added to the electrode. 4000 series of aluminum alloys have silicone added to make that grade.

2. ER5350

The ER4043 is the most commonly used MIG filler wire. It welds aluminum grades 5050, 5052, 5056, 5083, 5086, 5154, 5356, 5454, 5456. In most cases, the gas used is always 100% Argon and in rare cases, a helium/Argon mix may be used on base metals thicker than ½ of an inch. The electrodes designation is as follows:

- ER– An electrode or filler rod that is used in either a MIG wire feed or TIG welding.

- 5– The series of the aluminum. This electrode is made from a 5000 series aluminum.

- 356 – This number indicates the amount of Magnesium added to the electrode. 5000 series of aluminum alloys have Magnesium added to make this alloy.

Considerations When Choosing MIG Welding Wire

Neither type is superior compared to the other – rather, the right choice depends on your situation and preferences. Here are a few things to keep in mind when you pick MIG welding wire.

1. Desired Weld Cleanliness

As a rule, solid MIG welding wires used with shielding gases produce a cleaner weld with much less spatter compared to flux-cored wire. Spatter does not necessarily affect weld quality, but it may require additional grinding, polishing, and finishing to remove it before painting or other such surface preparations, so solid wire is more commonly used in these situations.

In making a MIG wire purchase, your last decision involves the quantity of wire and how it’s housed. For instance, Lincoln Electric offers ER70S-6 as a 44-pound spool or a 1,000-pound drum.

Obviously, the wire feed mechanism on the welding machine will dictate which option is chosen. (A small non-industrial MIG machine uses a much smaller spool than you see in the photo below.)

MIG wire can also be ordered in “TIG cut lengths”. This refers to the three-foot strands used in TIG welding. Diameter sizes in this case are not given in decimals but rather as normal TIG rod sizes, such as 1/16 or 3/32.

2. Workpiece Material

Different types of wire are used for different materials. ER70S-3 wire is often used for mild steel that’s clean, oil-free, and rust-free, while ER70S-6 contains a deoxidizer and is used for mild steel that’s contaminated with corrosion or mill scale.

3. Environment

In very windy or challenging outdoor environments, flux-core wire is usually a better option. The gas used to shield solid MIG welding wire may be blown away while welding in windy conditions, so unless a windscreen is used, this results in a lower-quality weld. Since flux-core wire contains gases that emerge when it’s heated, the metal is shielded more effectively in those conditions.

4. Wire Thickness

Once a wire type is determined for your welding equipment, two additional pieces of information are needed in order to purchase this consumable.

The first is the wire diameter, which is usually given in thousands of an inch. The most common sizes for welding on sheet metal are 0.35 and 0.45.

A 035-inch diameter wire is a standard used for most welds, but it may not be adequate for very thick pieces of metal. Multiple passes may be required to create a strong weld.

5. Weld Unit Power

This is closely related to wire thickness. The higher the voltage and power of a MIG welding unit, the higher the thickness it can accommodate. Using a thicker wire is not a good idea with lower-powered MIG welding units.

The lower overall amperage and output may result in a failure to melt the workpieces properly and create a quality weld. Always consult the manufacturer’s instructions to see the maximum recommended wire thickness.

Conclusion

No matter what type of MIG welding wire you buy, you should always make sure to invest in high-quality wire. Compared to lower-quality welding wire, quality MIG wire is more forgiving, can produce a sounder weld even in less-than-perfect conditions, and still represents only a fraction of the overall cost of welding.

As you can see, the many variables involved in choosing the right wire will take a while to learn. It’s a good idea to focus on the most common rod classifications at first and absorb the rest of the arsenal over time.

That said, as an entry-level welder, however, you may find yourself having to stock consumables or replace empty spools on MIG machines for seasoned veterans. So, exercising due diligence in correctly selecting and storing wire products is essential to preventing costly mistakes when a welding operation begins.

The American Welding Society has handbooks available for purchase, but the cost can be prohibitive. Check with your school or workplace to see if you can access a handbook and photocopy any info you need to place in your literature binder.