Welding is one process that has existed for a long time and still serves its purpose even to this day. There are many types of welds, and the type of project often determines the type of weld employed by manufacturers. One type of weld that is of great importance is tack welding.

So, Keep reading as we provide answers to what is tack welding and other important things you need to know about tack weld.

What Is a Tack Weld?

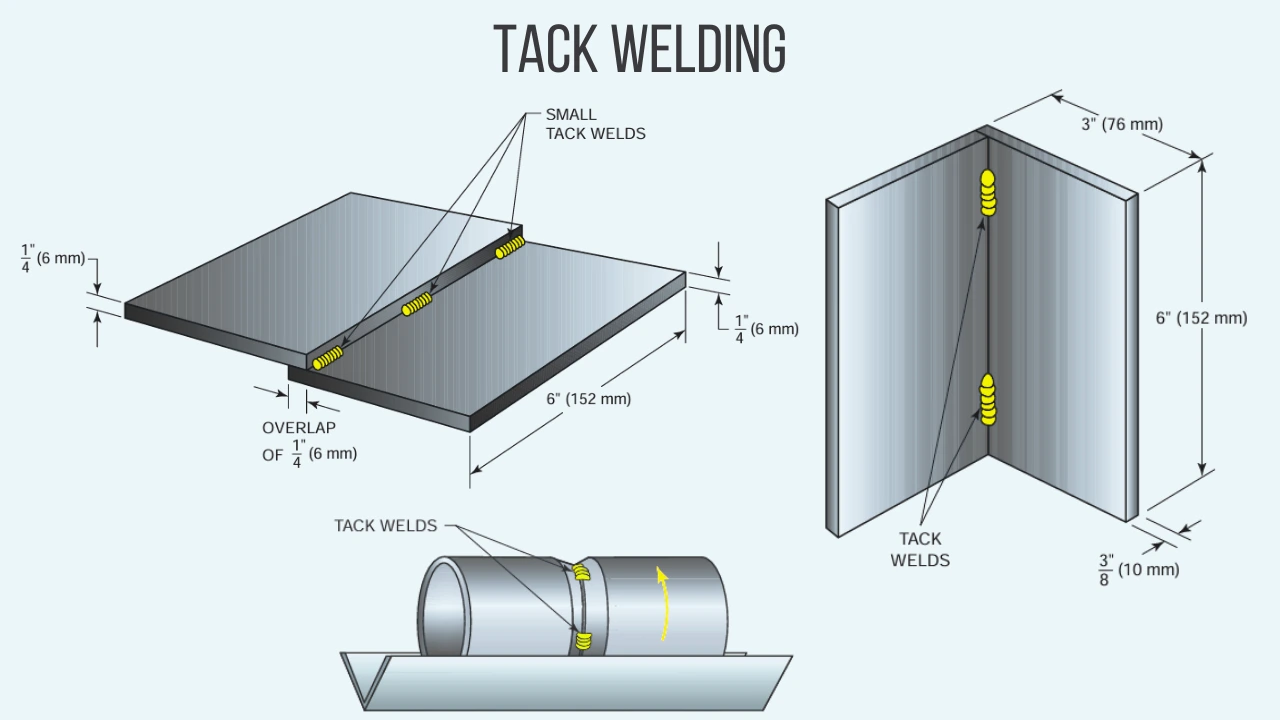

Tack welds are small and temporary welds that hold parts together ready for final welding. Using tack welds means that fixtures may not be required to hold parts together to create a finished weld. Tack welds maintain the desired alignment and gap between the pieces of metal being joined.

Making good tack welds is one of the keys to assembly work. Tack welds must also be small enough to be incorporated into the final weld without causing a discontinuity in its size or shape.

They must be strong enough to hold the parts in place for welding but small enough so that they become an unseen part of the finished weld. Deciding on the number, size, and location of tack welds takes some planning.

Things To Consider While Making a Tack Welds

Some of the factors to consider regarding the number of tack welds include the following:

- Thickness of the metal. A large number of very small tack welds should be used on thin metal sections, while a few large tack welds may be used for thicker metal parts.

- Length and shape of the joint. Obviously, short joints take fewer welds, but some long, straight joints may have very few tack welds compared to a shorter joint that is very curvy.

- Welding stresses. All welds create stress in the surrounding metal as they cool and shrink. Larger welds produce greater stresses that might pull tack welds loose from an adjoining part if the tack welds are not strong enough to withstand the welding stresses.

- Tolerances. The more exacting the tolerance for the finished weldment, the more tack welds are required.

- Fit-up. When custom bending parts during the fit-up process, it may be necessary to use a large number of small tack welds to keep the parts in alignment and make the bends more uniform.

Tack welds must be made in accordance with any welding procedure with an appropriate filler metal. They must be located well within the joint so that they can be completely remelted into the finished weld.

Post-tack welding cleanup is required to remove any slag or impurities that may cause finished weld flaws. Sometimes the ends of a tack weld must be ground down to a taper to improve their tie-in to the finished weld metal.

Make sure that your tack welds are not going to be weld defects in the completed weldment. A good tack weld is one that does its job by holding parts in place yet is undetectable in the finished weld.

On harder metals like steel, you can often hear a tack weld break; however, for some soft metals like aluminum, the tack weld may separate quietly. Depending on the type of metal and its size and thickness, a breaking tack weld can make a small, sharp snap or a deep, resounding thump.

You might hear one break while you are welding or sometime afterward. Do not assume that a broken tack weld has no effect and continue to weld. A broken tack can allow parts to shift well out of tolerance.

If you continue to weld, it may be impossible to pull the loose part back into position, which could result in the weldment not meeting its specifications. Sometimes this is referred to as “making scrap metal” and not a weldment.

Types of Tack Welding

There are different types of tack welding, and each one has its best-use scenario and purpose. Here we will highlight the five most common types welders use.

Standard Tack Weld

Standard tack welds sit within the joint and are intended to be consumed by the final weld. A standard tack weld will hold the pieces together in the proper fit throughout the final welding process.

Bridge Tack Weld

If a fit-up leaves a gap to be filled with weld, the bridge tack is used across the gap. These gaps may occur when the material is cut too short in the shop or arrives from the supplier with distortion.

One way to bridge the gap is to apply a weld in a sweeping motion. You must be careful not to use too much weld at once, so it doesn’t get too hot and fall through the gap. Taking breaks between quick passes will keep the temperature down.

Another method is to apply small tacks to each side, alternating to allow the other side to cool. Eventually, you will reach the middle of the gap and join both joint sides.

This method is more time-consuming and works best with MIG or flux-cored welding. Remember, bridge tacks do not penetrate the joint’s root, and you grind them off after the first root pass.

Thermit Tack

Thermit tack involves mixing pure magnesium metal, aluminum powder, and iron oxide powder. The reaction produced by this mixture is often very hot, above 4000 degrees Fahrenheit.

Hot Tacking

A hot tack weld is formed by depositing excess filler metal into the gap between metal parts and then using a hammer to close it up.

The hot tacks are known as cleats or dogs. While this is a quick and efficient method of closing a gap between two metal parts, products that use this method are unlikely to pass quality checks.

Ultrasonic Tack

Ultrasonic tack involves creating a tack using an electric or gas welding machine. This welding creates several short pushes or pulls that move through the parts a welder wants to weld at ultrasonic speed.

Then welders create molten material that fuses the parts by pushing welding wire hard enough into a base metal.

Four Forms of Tack Welds

The forms of tack welds help hold parts together before full welding. They also help attach parts. There are four main forms.

- Square: This form of tack welding is strong. Created by making tack welds in a square pattern, this form of tack is ideal for joining two parts at a right angle.

- Vertical: This involves laying a tack between two metal pieces so that it runs vertically from top to bottom of the pieces. For instance, tacking the top piece is best when you have two pieces that you want to align vertically.

- Right Angle: This type of tack is ideal when welding two pieces of metal with a perpendicular relationship. For instance, tacking the bottom piece is ideal if you have two pieces that you want to tack at a right angle to each other.

- Right Angle Corner: If joining two perpendicular pieces would produce a T-shape, then using the right-hand corner is ideal. Here the welder joins the pieces at their 90-degree point.

The Pros and Cons of Tack Welding

Advantages Of Tack Welding

- These temporary welds hold parts together in a solid joint geometry.

- Enables fast disassembly, if needed.

- You can weld without using bulky fixtures.

- It’s easier to hold the joint together in tight spaces.

- Sets and maintains a joint gap.

- Provides mechanical strength against base metal weight if moved.

- It helps to prevent distortion during welding.

- It’s relatively easy after you learn to avoid the pitfalls.

- You can tack weld almost any material.

Disadvantages of Tack Welding

- It’s temporary and produces weak bonds.

- Joint quality can be impaired if tack welding isn’t carried out correctly.

- It exacerbates the build-up of oxides.

- Parts will need to be cleaned afterward.

- When tack welding some materials, such as hard and brittle steel, specialist knowledge and skill is required, as it can leave some spots vulnerable to cracking.

- Some materials don’t handle the rapid, localized heating and cooling of tack welding very well.

- It isn’t easier to carry out on large parts or areas near the edge of parts.

Wrapping It

Tack welding is used to temporarily hold two pieces of metal together ahead of a final welding procedure. These welds make sure the two workpieces are rigidly aligned as desired and that the joint gap and orientation are correct.

Tack welds can also reduce distortion in the metals while undergoing their final weld, reinforcing or even replacing fixtures. This is useful for low-volume or one-off jobs where fixtures may not prove to be worth their cost.

Designed to be small and easily removed, tack welds still need to be strong enough to serve their purpose without compromising the base materials.