What is Plasma Arc Welding?

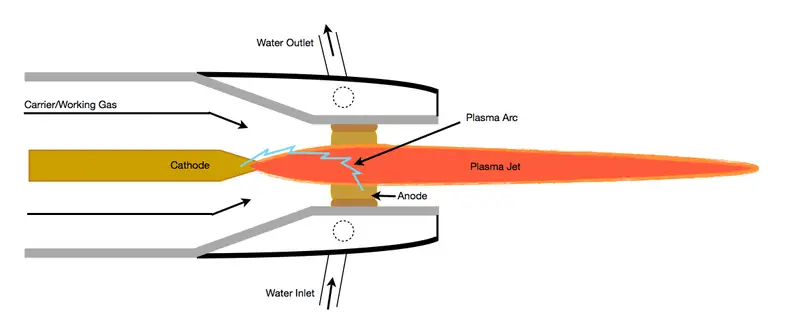

Plasma arc welding (PAW) is an arc welding process very similar to TIG welding in that the arc is created between a pointed tungsten electrode and the workpiece. However, by positioning the electrode inside the torch body, the plasma arc can be separated from the shielding gas envelope. Plasma is then forced through a finely bored copper nozzle that constricts the arc.

Plasma welding is a process in which a plasma arc is ignited between the electrode and the base material and used for welding. It is classified as a non-consumable type of electrode and, like TIG welding, uses a tungsten rod as the electrode.

The difference is that it uses a nozzle to cover the electrode and a plasma gas to prevent the arc from spreading.

The resulting high heat concentration enables high-speed welding with a narrow bead and less distortion. Due to its highly directional arc, plasma welding is suitable for fillet welds and can eliminate spatter.

Its low electrode consumption allows high-quality welding over a long period of time. Although the welders are expensive compared to TIG welders, the running costs are low. This is one of the best methods for automatic welding.

The pilot gas (inert gas) flows through the torch and is ionized (plasma conversion) by the heat of the pilot arc. The ionized pilot gas forms a plasma jet, ejects from the nozzle hole, and acts as a conductor for the arc current.

This narrows the arc to give it high energy density and shoot out of the insert tip hole. Arc spread is limited to about a quarter of that in TIG welding, resulting in a higher current density arc.

Bore Diameter

Three operating modes can be produced by varying bore diameter and plasma gas flow rate:

Micro plasma: 0.1 to 15A

The microplasma arc can be operated at very low welding currents. The columnar arc is stable even when the arc length is varied up to 20mm.

Medium current: 15 to 200A

At higher currents, from 15 to 200A, the process characteristics of the plasma arc are similar to the TIG arc, but because the plasma is constricted, the arc is stiffer. Although the plasma gas flow rate can be increased to improve weld pool penetration, there is a risk of air and shielding gas entrainment through excessive turbulence in the gas shield.

Keyhole plasma: over 100A4

By increasing welding current and plasma gas flow, a very powerful plasma beam is created which can achieve full penetration in a material, as in laser or electron beam welding.

During welding, the hole progressively cuts through the metal with the molten weld pool flowing behind to form the weld bead under surface tension forces. This process can be used to weld thicker material (up to 10mm of stainless steel) in a single pass.

Construction of the Plasma Arc Welding Machine:

The Plasma Arc Welding setup consists of the following components:

- Power Supply

- Plasma Welding Torch

- Water re-circulator

- Tungsten Electrode

- Shielding Gas

- Plasma Gas

- Torch Accessory Kit (Tips, ceramics, collets, electrodes set-up gages)

- Filler Material

Let me give you a brief overview of each component.

1. Power Supply:

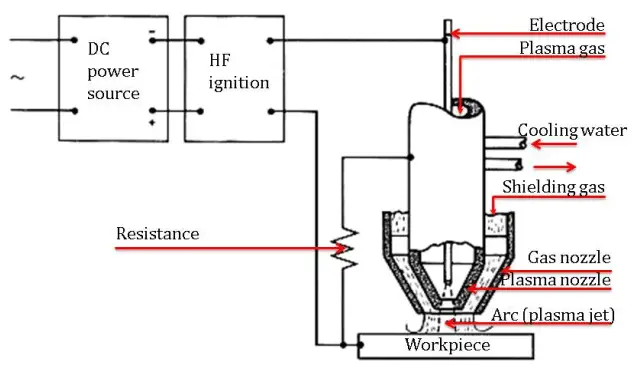

The plasma arc welding process needed a high-power DC supply to generate the electric spark in between the tungsten electrode and welding plates

This welding can weld at a low 2 amp and the maximum current that it can handle is about 300 amp. It needs about 80 volts for proper working.

The power source consists of a transformer, rectifier, and control console.

2. Plasma Welding Torch:

This is the most important part of the plasma welding process.

This torch is quite similar to used in TIG welding.

PAW torches are water-cooled because the arc is contained inside the torch which produces high heat, so a water jacket is provided outside the torch.

3. Water Re-circulator.

This mechanism is used to cool the welding torch by the continuous flow of water outside of the welding torch.

4. Tungsten Electrode.

In this machine, we use a no-consumable tungsten electrode. As we know tungsten can withstand very high temperatures.

5. Shielding Gas.

In this welding process, we use two inert gases. We need to maintain a low pressure to avoid turbulence while welding due to this low-pressure gas welding shield is formed weekly, that’s why we need to charge another inert gas through the outer portion of the welding force in a high flow rate, to make the weld shield sustainable.

The inert gases which are used in this process can be helium, argon, and also hydrogen as per the need, and it totally depends on the temperature.

6. Plasma Gas.

It is an ionized hot gas composed of nearly the same number of electrons and ions. It has sufficient energy to free electrons from molecules, atoms, and electrons to synchronize.

It is the main energy source of this welding.

7. Torch Accessory Kit.

These kits are used to expand the performance of the welding torch.

8. Filler Material.

In Plasma welding there is no filler material is used. If the filler material is used, then it is directly fed into the weld zone.

How Does Plasma Welding Work?

A plasma is a gas that is heated to an extremely high temperature and ionized so that it becomes electrically conductive. Similar to GTAW (Tig), the plasma arc welding process uses this plasma to transfer an electric arc to a workpiece. The metal to be welded is melted by the intense heat of the arc and fuses together.

In the plasma welding torch, a Tungsten electrode is located within a copper nozzle having a small opening at the tip. A pilot arc is initiated between the torch electrode and the nozzle tip. This arc is then transferred to the metal to be welded.

By forcing the plasma gas and arc through a constricted orifice, the torch delivers a high concentration of heat to a small area. With high-performance welding equipment, the plasma process produces exceptionally high-quality welds.

Plasma gases are normally argon. The torch also uses a secondary gas, argon, argon/hydrogen, or helium which assists in shielding the molten weld puddle thus minimizing oxidation of the weld.

Advantages of Plasma Arc Welding

The advantages of Plasma Arc Welding are the following:

- Torch design allows better control of the arc.

- This method provides more freedom to observe and control the weld.

- The higher heat concentration and plasma jet allow faster travel speeds.

- The high temperature and high heat concentration of plasma allow the keyhole effect.

- This provides complete penetration with the single-pass welding of many joints.

- The heat-affected zone is smaller compared to GTAW (Gas tungsten arc welding).

- It uses less current input as compared to other welding processes.

Disadvantages of Plasma Arc Welding:

The disadvantages of Plasma Arc welding are:

- It produces wider welds and heat-affected zones compared to LBW and EBW.

- Plasma welding equipment is very costly. Hence it will have a higher startup cost.

- It requires training and specialization to perform plasma welding.

- It produces ultraviolet and infrared radiation.

- The method produces higher noise on the order of about 100 dB.

- The torch is bulky and hence manual welding is a bit difficult and requires training as mentioned.

Applications of Plasma Arc Welding:

The application of Plasma Arc welding is:

- This welding is used in the marine and aerospace industries.

- This is used to weld pipes and tubes of stainless steel or titanium.

- It is mostly used in electronic industries.

- Also, this is used to repair tools, die, and mold.

- This is used for welding or coating a turbine blade.

So, this is all about Plasma Arc Welding Machining, I hope you enjoyed this article. I also wrote articles on some other welding processes to check out those too. Moreover, do not forget to share the article on your favorite social platform.