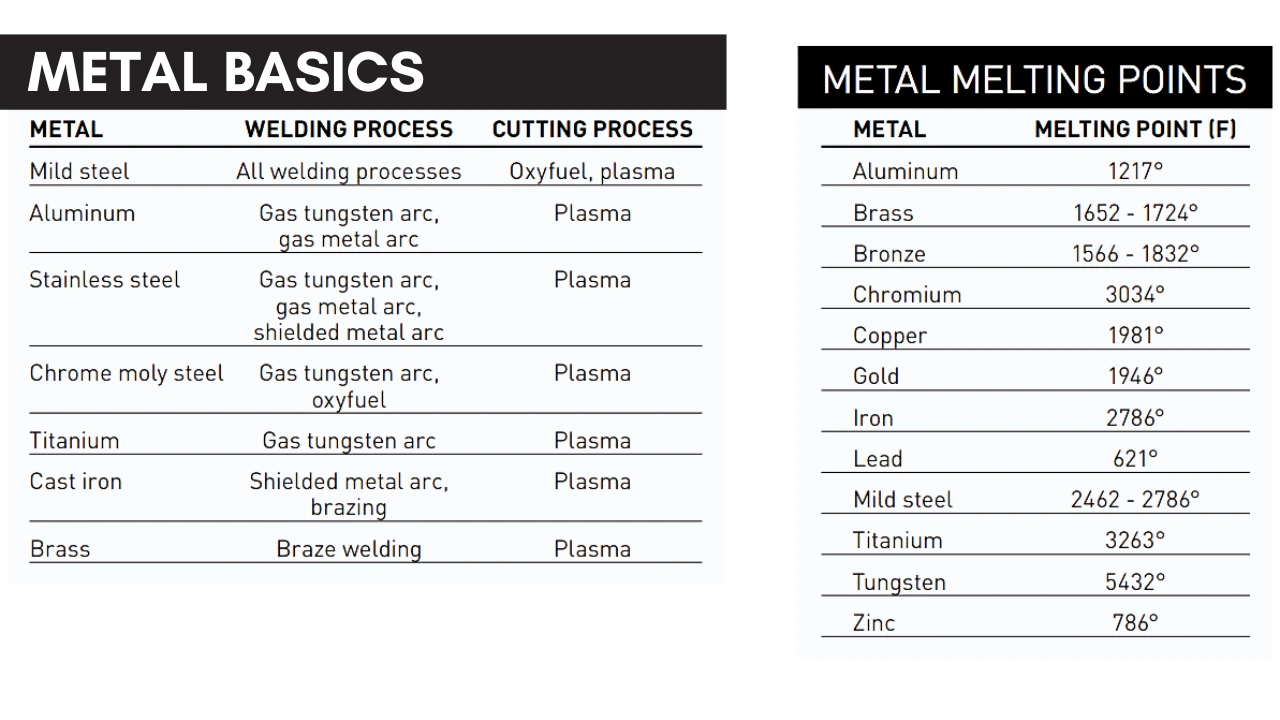

The appropriate classification of a metal for welding is based upon its composition (whatever base metals have been used and the addition of alloys that enhance its strength, toughness, impact resistance, corrosion resistance, or ductility).

It is necessary to identify the metal type as well as the base metal and the alloying elements that may have been added.

Metals will generally be categorized as either ferrous or nonferrous. Ferrous metals have iron as the main alloy and include cast iron, forgedsteel, mild steel, and stainless steel. Ferrous metals also have magnetic properties.

Nonferrous metals include the pure elements (for example aluminum). Since they do not contain iron, they do notmagnetize and have a lower melting point. It is critical that the base and filler metals match so you are welding similar metals.

Since welding involves melting and fusing the base and filler into one new metal, melting points, and characteristics of the metals to be welded must be similar. Dissimilar metals can be joined by brazing, braze-welding or soldering, since none of these processes melt the base metels.

Ferrous metals all have some amount of iron combined with alloys including carbon, chromium, molybdenum, manganese, and nickel. Each alloy contributes a property of to the low-carbon steel.

Mild steel (or low-carbon steel) is by far the most common and easiest to work with. It can be cut and welded using all of the processes described in this book. It is in almost all of the metal items you use, make, or repair, including automotive bodies, bicycles, railing, furniture, cabinets, and shelving.

Higher carbon content will make steel harder as it adds carbon; however, it will also make the steel more brittle and more difficult to cut, or weld. High-carbon steels are used for cutting tools like drill bits, different machine bits and knife blades.

With other alloying elements (like chromium and nickel) added to low-carbon steel one can then produce ‘stainless steel’. Stainless steel, does not oxidize (rust) easily, so is best cut, or welded using a plasma cutter.

As with low-carbon steel, filler metal must be selected, which is a good match to the alloy’s elements to assure a good quality weld does not result.

Aluminum is the most common nonferrous metal clearly due to its light weight and corrosion resistant properties. Aluminum, like steel, has many alloys and is frequently heat-treated to increase strength.

Aluminum is used for many engine parts, boats, bicycles, furniture, kitchenware and has recently been adopted as fully aluminum frames on many large-volume automobiles.

There are several characteristics of aluminum that makes working with it difficult to produce a successful welded joint it will not change color when melted, it dissipates heat quickly, and once removed from heat it instantly develops an oxide layer that melts at a higher temperature versus the base metal itself resulting in overheating, extreme distortion and destruction of the metal.

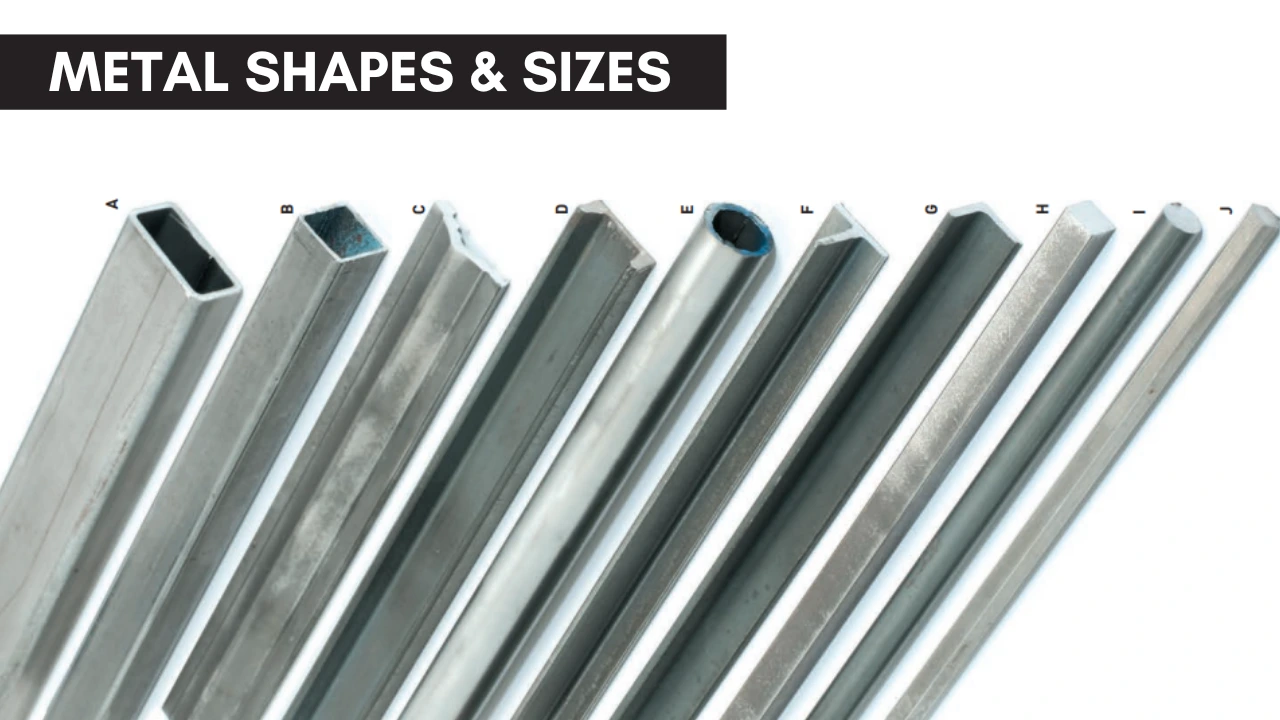

Metal Shapes & Sizes

Mild steel and most metals come in a variety of configurations, sizes, and thickness varieties. Metal thickness can be specified as, fraction of an inch, decimal, or gauge. Sheet metal will usually be 3 /16 inch thin or less and designated as a gauge number, while plate will be ¼ inch or thicker.

Structural metal typically is identified by its length, width, and by its wall, leg, or web thickness. Some of the most common structure types and size callouts are:

- A. Rectangular tubing serves purposes such as structural framing, trailers, and furniture. The dimensions for rectangular tubing are expressed as width x height x wall thickness x length.

- B. Square tubing serves purposes such as structural framing, trailers, and furniture. The dimensions for square tubing are expressed as width x height x wall thickness x length.

- C. Rail cap is used to create handrails. The dimensions of rail cap are the overall width and width of the channels on the underside.

- D. Channel is used for creating handrails. For truck frames and structural items (for example, bridges or industrial items) can use very large channels. The legs (or flanges) make it much stronger than flat bars. The dimensions of a channel are expressed as flange thickness x flange height x width (outside) x length.

- E. Round tubing is not the same as a pipe. Round tubing is used for a structural item, pipe is for transporting liquids or gases. Dimensions for round tubing are specified by outside diameter (OD) x wall thickness x length.

- F. T-bar dimensions are specified as width × height × thickness of flanges × height.

- G. Angle or angle iron has a wide variety of structural and decorative applications. The dimensions for the angle are specified as thickness (flange) x width (leg) x height (leg) x length. Angles can be equal length legs or unequal length legs.

- H. I. J. Square, round or hex bar (hex bar) dimensions are specified by width / outside diameter (flat to flat for a hexagonal bar) x length.

Flat bar/strap (not shown) comes in various sizes, but is usually not wider than 12″ for flat bars are specified by thickness × width × length.

Sheet metal (not shown) is 3 ⁄16″ or less and may be referred to by gauge number. Plate is 1 ⁄4″ or greater and is identified by its thickness in fractions of an inch.

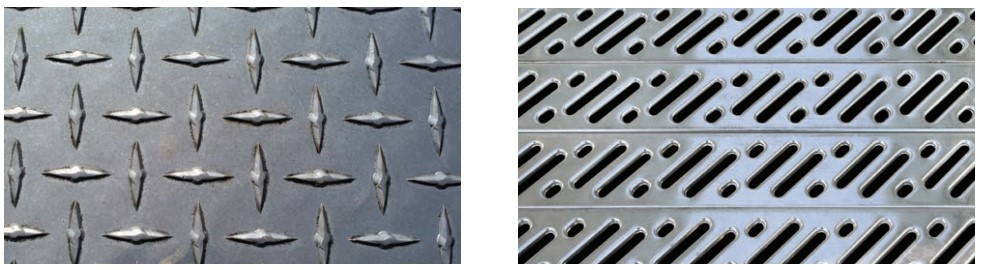

Diamond plate is utilized as heavy-duty siding on carts, tool boxes and the like, because of its strength and durability. It is also used in decorative applications. It is sold as length × width × thickness.

Perforated sheet metal is used for industrial shelving, fences, stair treads, floor drain grates, and many decorative sidings and top treatments.

There are many patterns and styles to choose from. Sometimes they are referred to as perforated metal screens. Perforated sheets are sold as length × width × thickness. Lighter weight sheets are sold by the yard in rolls.

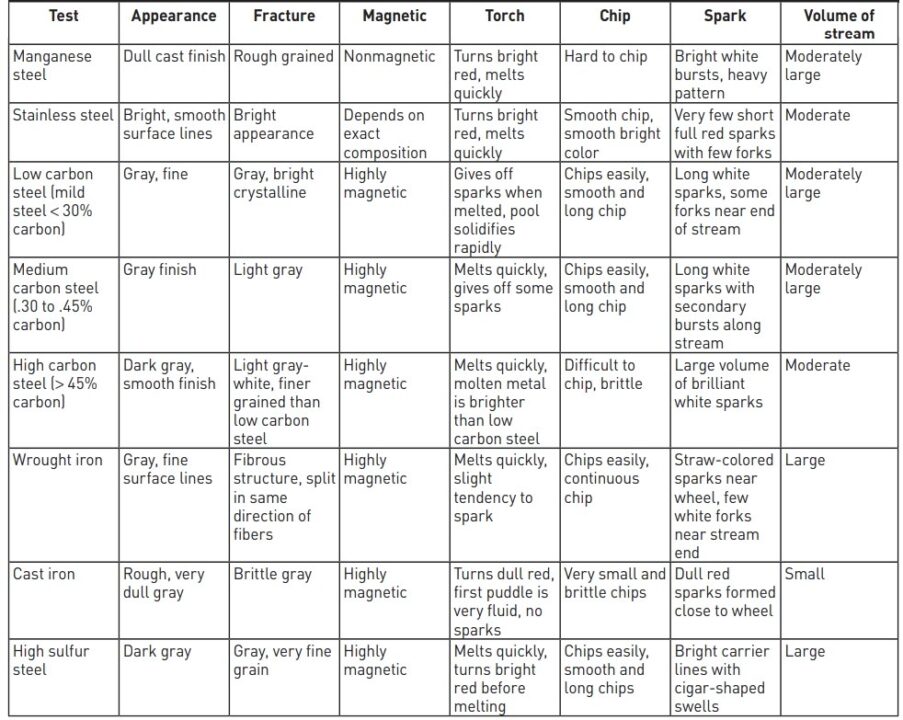

Metal Identification Chart

Metals Purchasing

Obtaining finished metal products can be difficult. General merchandise available at home centers and hardware stores come in less than desirable shapes or sizes and can be very expensive; if you order online or from a catalog, costs for heavy items from shipping can get limiting.

However, with a little searching, you can find most things, and at a price that won’t break your budget. Once you locate a metal supplier, the supplier will allow you to purchase metal either by weight, or by linear foot.

Small pieces of mild steel at a home center or hardware store could cost $3.00 to $5.00 per pound, while, depending on the type of material, price at a larger steel supplier could be as low as $1.00 per pound.

Almost all steel suppliers have a bin or rack of odd and ends, where the materials available are discounted even further than retail or wholesale pricing.

Although high, stainless steel and aluminum should be considered with mild steel. Because the materials are available in three- or four-foot lengths at a home center or hardware store, handling them is easier than the 10, 12, or 20-foot lengths from a steel supplier, per typical stock sizes.

Some steel suppliers distribution decorative metal products, but many specialty products, like wrought iron railings, decorative accessories, and welding components, can only be ordered from a catalog.

Metal Cleaning & Preparation

A well-prepared joint is the first step to a successful weld. The more effort put into cleaning and preparing the welding joint, the better quality weld, with an acceptable appearance, you will achieve.

When working with hot rolled steel (HRS), mill scale, which is a thin layer of oxide on top of the steel that has naturally formed when passed through the mill at a hot temperature, needs to be removed.

Once again, everything needs to be cleaned to remove any oil, dirt, rust, and, most importantly the mill scale from all parts of the project.

Cleaning can be time-consuming, but it is necessary for a durable project with little maintenance or repair. For any project to be painted or powder-coated, every part of the project should be cleaned.

Do not let parts rust or otherwise obtain a weathered appearance through the passing of time; you should thoroughly clean all areas to be welded.

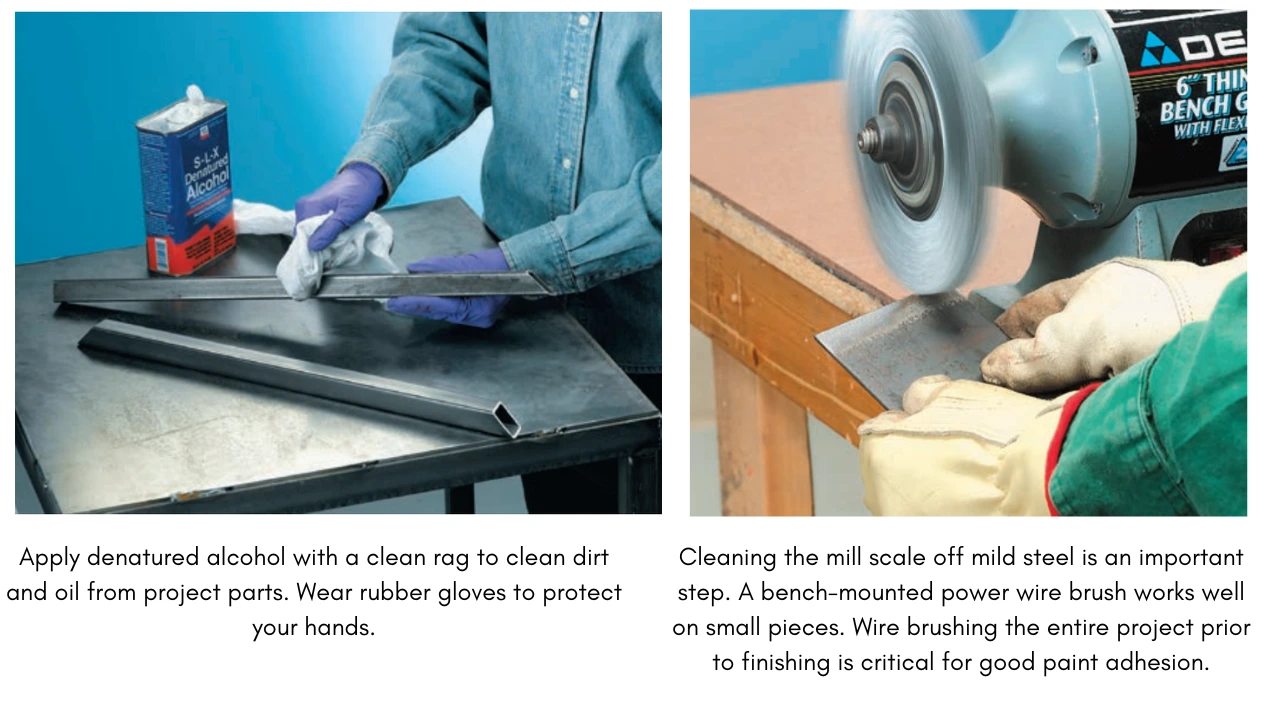

Cleaning an HRS part involves the removal of all grease, oil, or dirt by wiping the part down with denatured alcohol, acetone, or a commercial degreaser. Alcohol is the best option because it does not have a strong order, and will not dissolve or ruin plastics as acetone can do.

The commercial degreasers can certainly work but will leave a residue and so can acetone; both products may degrade the overall quality of the weld or finish of the final product. Once the grease, oil, and dirt has been removed from the part’s surface, mill scale needs to be removed.

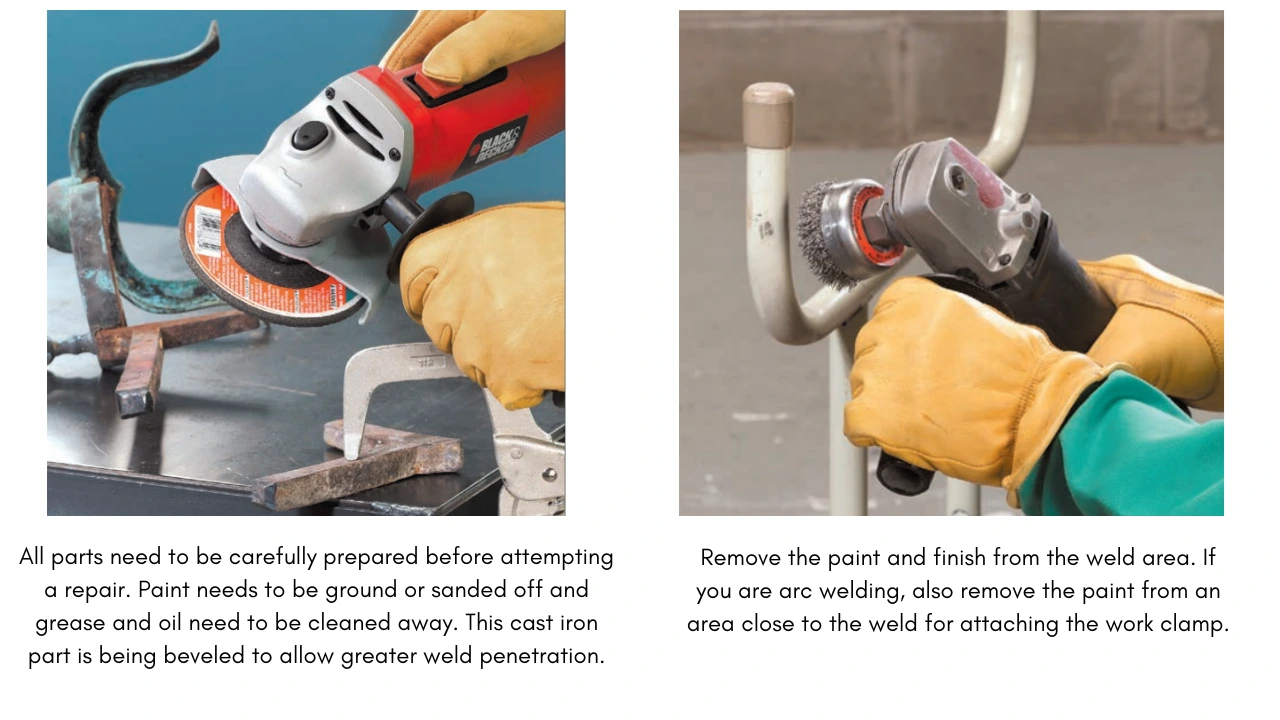

Mill scale can be removed by: wire brushing, grinding, sanding, or sandblasting the part. Using a bench-mounted grinder with a wire brush works very well for small parts, and for the ends of smaller parts, however, it cannot be used on larger surfaces.

For larger surfaces, you will require an angle grinder with a grinding wheel, wire brush, or flap wheel attachment, or you can use a hand-held, cordless drilling machine with a wire brush or wire brush cup.

Remember, any time you are using tools that can cause injury, you need to wear appropriate PPE – primarily having safety glasses, face shield and long sleeves – as items such as wire can be thrown from the brush, and strike your eyes and body.

Additionally, you should never force the angle grinder or drill and apply too much pressure to either tool, as they can kick back and cause serious injury. Once all your parts have been cleaned and you remove the mill scale, you should do the last step of the process, prior to the metal rusting.

Metal Weld Repairs

Once you get into welding, there will be many opportunities to do repairs. Once your friends and neighbors find out that you can do repairs, there will be even greater possibilities.

Repairing welds can be really difficult and can even be dangerous if you are unsure of the type of material and what the part represented. When in doubt, leave it out, especially on a vessel or drum where you have no idea of the previous contents.

Always consider your welding skills, the repair difficulty and the use of the repaired item. Any type of structural repair or vehicle repairs, such as stairways, ladders, trailers or chassis, needs to have the same safety value as it had prior to being repaired.

1. Determining Why the Item Broke.

In the case the failure is caused by a poorly done weld then the repair may consist of simply grinding out the welded region, tack the area together again and make a satisfactory weld.

If a part has failed due to metal fatigue simply welding over the area where it cracked may just cause cracks in other locations. You should investigate and ask questions and seek the advice of mentors or other people with suggestions of how to appropriately repair the failed item.

2. Determining the Base Metal.

All ferrous metals (iron-based materials) will be attracted to a magnet; however, not all steel and cast iron are created equal. Mild steel is not the same as stainless steel (which may also be nonmagnetic). Welding processes vary between them.

Similarly, Aluminum will not be attracted to a magnet.ist but also easily distinguished by weight – again, understand what alloy is present with the aluminum! Not all aluminum is weldable.

To complicate matters further, many manufactured metal parts are not only alloyed but may have also been heat-treated.

After all that, based on the physical shape alone, it is often simply impossible to tell what the base metal composition is without the manufacturer’s specifications.

Before an attempt to repair a specific compound or alloy, it is useful to understand the history of heat and welding, too, have consideration of those affects as well.

3. Repair It.

Once you have determined that completing a repair is feasible, the next step is to properly clean and prepare the area to be welded by removing all dirt, oil, and paint or finishes from the surface.

If one of the arc welding processes is being used to make the repair, then an area must be cleaned down to bare metal so that the work clamp can be properly secured.

If your break is at a welded joint, you also need to remove some of the old weld beads to guarantee complete penetration into the base metal.

Mild steel is by far the easiest material to repair. Simply prepare the metal as we discussed on the topic of metal cleaning and preparation, and you should be able to finish the weld using any of the arc welding processes.

Both cast iron and cast aluminum need to be preheated before welding to limit cracking due to thermal tectonic shifts. Twice either bronze weld or shielded metal arc weld your cast iron using cast iron electrodes. In either case, the preheat temperature should be 450°F before welding.

If the size of the piece permits, place it into an oven at that temperature, i.e. between 400 and 500 degrees Fahrenheit.

If that is not possible, use an oxyacetylene or oxypropane rosebud or heating tip. There are goodies like temperature crayons that melt at certain temperatures which can be used to mark your metals preheating temperature.

Post-weld heat and penning may also be necessary to relieve some stress while allowing the part to return to ambient temperature at a controlled rate to further reduce the risk of cracking.

Not all aluminum can be welded, but if an aluminum part shows signs of past repairs, you are generally able to fix it. In addition, if it is possible to determine the composition of the base metal, try to match the filler metal with it.

Some filler metals have multi-application usage on more than one alloy. Look for recommendations from the manufacturer or a professional at the welding supply shop.

Stainless steel comes in allotments, so be sure to pick the right filler metal for the base metal. Do not clean stainless steel with a wire brush because mild steel wire will contaminate your base metal. Bring a flap wheel, emery cloth or abrasive pad for cleaning.

FAQs

How do you prepare base metal for welding?

Surface impurities or defects on metal can reduce the quality of your weld. There are several methods you can use to prep metal for welding. Methods include using cloth and solvent, wire brushing, sanding with sanding discs, sheets, or belts, and using an angle or die grinder.

How do you prep metal for welding?

Before you weld, you should clean the surface with acetone to clear away contaminants. Even if you’ve removed all the rust and paint you’ll still need to wipe down the metal.

What is base metal in welding?

Base Metal – The metal to be/that is welded or cut. Basic Electrode – An electrode that has coating high in limestone and other ingredients low in hydrogen content that form a basic slag. Bevel – An angular type of edge preparation. Butt Joint – A Joint between two members aligned approximately in the same plane.

What are the necessary preparations before welding?

Once the material is cut and beveled, it’s time to prepare the surface for the initial welding pass. Removing any mill scale, chemicals, contaminants, and coatings from the base material helps ensure proper weld penetration and eliminate impurities, porosity, and inclusions.

How to prepare thick mild steel for welding?

It’s best to use a grinding wheel to lightly remove the top layer and make a shiny-clean metal surface. When welding thick mild steel, you may also need to prepare the edges by grinding the joint into a single-bevel or double-bevel (V-groove) configuration.

What is the minimum thickness of base metal for welding?

The minimum thickness that can be effectively welded with a TIG welder is typically around 0.020 inches (0.5 mm). TIG welding offers precise control over heat input, making it suitable for thin materials without causing excessive distortion or burn-through.